Custom LiPo Battery: OEM Lithium Polymer Battery Solutions Built for Your Product

What Is a Custom LiPo Battery?

A custom LiPo battery is a lithium polymer battery designed and manufactured according to specific application requirements, rather than using standard off-the-shelf battery models.

From my experience working with OEM customers, customization usually involves much more than size adjustment. It includes electrical performance, safety protection, mechanical structure, certification compliance, and long-term reliability.

Why Off-the-Shelf LiPo Batteries Often Fail in Real Products

Most customers come to us after encountering one or more of these issues:

| Common Problem | Root Cause |

|---|---|

| Battery doesn’t fit enclosure | Fixed pouch dimensions |

| Device shuts down unexpectedly | Incorrect discharge rate |

| Battery swelling | Incompatible charging design |

| Certification failure | Non-compliant cell materials |

A custom LiPo battery eliminates these risks before mass production, not after.

Key Customization Options for LiPo Batteries

Battery Size & Shape Customization

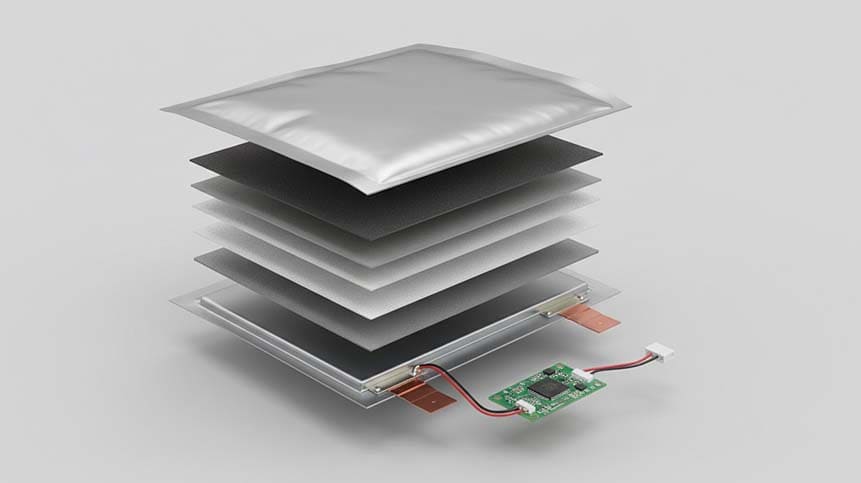

LiPo batteries use aluminum-laminated pouch cells, allowing flexible shapes such as:

- Ultra-thin batteries (≤3.0mm)

- Curved or L-shaped designs

- Stacked multi-cell structures

This is critical for wearables, medical sensors, and compact IoT devices.

Voltage & Capacity Design

We design voltage and capacity based on real load profiles, not theoretical values.

| Parameter | Custom Range |

|---|---|

| Nominal Voltage | 3.7V / 7.4V / 11.1V |

| Capacity | 50mAh – 20,000mAh |

| Discharge Rate | 0.2C – 30C |

PCM / Protection Circuit Customization

A custom PCM protects against overcharge, over-discharge, overcurrent, and short circuit. For medical or industrial devices, we often design dual-layer protection logic.

Custom LiPo Battery Manufacturing Process

From concept to mass production, our OEM process includes:

- Requirement analysis

- Cell selection & simulation

- PCM schematic design

- Sample prototyping

- Safety & reliability testing

- Certification support

- Mass production & aging test

This structured process dramatically reduces field failure risk.

Safety Standards & Certifications for Custom LiPo Batteries

Depending on target market:

| Market | Required Certifications |

|---|---|

| Global Shipping | UN38.3 |

| Consumer Electronics | IEC 62133 |

| Medical Devices | IEC 60601 |

| North America | UL 2054 |

| Europe | CE, RoHS, REACH |

Certification planning should start during battery design, not after.

Data Support: LiPo vs Li-ion Battery Comparison

| Feature | LiPo Battery | Cylindrical Li-ion |

|---|---|---|

| Shape Flexibility | ★★★★★ | ★ |

| Energy Density | High | Very High |

| Weight | Lighter | Heavier |

| Customization | Excellent | Limited |

| Typical Applications | Wearables, Medical | Power tools, EV |

Application Scenarios for Custom LiPo Batteries

Medical Devices

- Patient monitors

- Infusion pumps

- Portable diagnostic tools

Wearable & IoT Devices

- Smartwatches

- GPS trackers

- Sensors

Industrial Equipment

- Handheld terminals

- Wireless controllers

- Backup power modules

How to Choose a Reliable Custom LiPo Battery Manufacturer

From my professional perspective, you should evaluate:

- Engineering capability

- Cell traceability system

- In-house testing labs

- Certification experience

- Long-term supply stability

The cheapest quote is often the most expensive mistake.

MOQ, Lead Time & Cost Factors

| Item | Typical Range |

|---|---|

| Sample MOQ | 5–20 pcs |

| Mass Production MOQ | 500–2000 pcs |

| Sample Lead Time | 7–15 days |

| Mass Production | 20–30 days |

Why OEM Clients Choose A&S Power

- 15+ years in lithium battery manufacturing

- Focus on custom LiPo batteries

- Medical & industrial project experience

- Stable global supply chain

- Engineering-first communication

FAQ – Custom LiPo Battery

Can you design batteries based on enclosure drawings?

Yes. We often start from mechanical constraints and reverse-design the battery.

Do you support low-volume projects?

Yes. We support startups and pilot projects.

How long does custom battery development take?

Typically 2–4 weeks including samples.

Can you help with certification?

Absolutely. Certification support is part of our OEM service.

If you’re developing a product that requires a custom LiPo battery solution, talk directly with our engineering team. Share your application details, and we’ll help you design a battery that is safe, reliable, and production-ready.

-

May.2026.02.27Lithium-Ion Batteries: The Six Constraints Blocking the Path to PerfectionLearn More

May.2026.02.27Lithium-Ion Batteries: The Six Constraints Blocking the Path to PerfectionLearn More -

May.2026.02.25Li-Polymer Battery 5000mAh: Complete Technical & OEM GuideLearn More

May.2026.02.25Li-Polymer Battery 5000mAh: Complete Technical & OEM GuideLearn More -

May.2026.02.24The Unparalleled Advantages of Lithium-Ion Batteries Over Traditional BatteriesLearn More

May.2026.02.24The Unparalleled Advantages of Lithium-Ion Batteries Over Traditional BatteriesLearn More -

May.2026.02.243.6 Volt Battery: Complete Technical Guide for Engineers & BuyersLearn More

May.2026.02.243.6 Volt Battery: Complete Technical Guide for Engineers & BuyersLearn More -

May.2026.02.24What Is a 3.8V LiPo Battery? A Complete Engineering & OEM GuideLearn More

May.2026.02.24What Is a 3.8V LiPo Battery? A Complete Engineering & OEM GuideLearn More