How to Keep Batteries Warm: Key Strategies for Performance

Introduction

Lithium-ion batteries, including LiFePO4 types, operate best within a narrow temperature range — typically between 20°C and 25°C. When exposed to cold environments, batteries can experience reduced capacity, slower discharge rates, and even permanent damage if charged below 0°C.

Extreme cold can also increase the risk of overcharging and internal stress, which shortens battery lifespan. Therefore, protecting batteries from the cold is essential for maintaining performance, safety, and reliability.

1. Passive Warmth Solutions

Passive methods are simple yet effective for maintaining temperature stability without continuous power consumption. These techniques are ideal for most general applications.

1.1 Insulation

Wrapping batteries in foam or insulated enclosures helps retain internal heat and prevents rapid temperature drops. This thermal barrier minimizes exposure to freezing conditions.

1.2 Battery Blankets

Battery blankets are specialized, form-fitting covers made from high-grade insulation materials.

They help:

-

Maintain a consistent internal temperature

-

Extend cycle life by reducing temperature stress

-

Provide easy installation and long-term reliability

1.3 Heated Enclosures

For stationary applications, electrically heated enclosures trap and distribute heat evenly around battery packs. These can be designed for various sizes, ensuring stable performance even in sub-zero environments.

1.4 Charge Maintenance

Before cold exposure, ensure batteries are fully charged. Low charge levels increase internal resistance and make batteries more vulnerable to cold-related degradation.

1.5 Avoid Overloading

Avoid operating batteries near their maximum current or voltage limits in freezing conditions. Cold increases internal resistance, which can lead to performance loss or stress damage if overloaded.

2. Active Temperature Control

For extreme cold environments, active temperature regulation is more reliable.

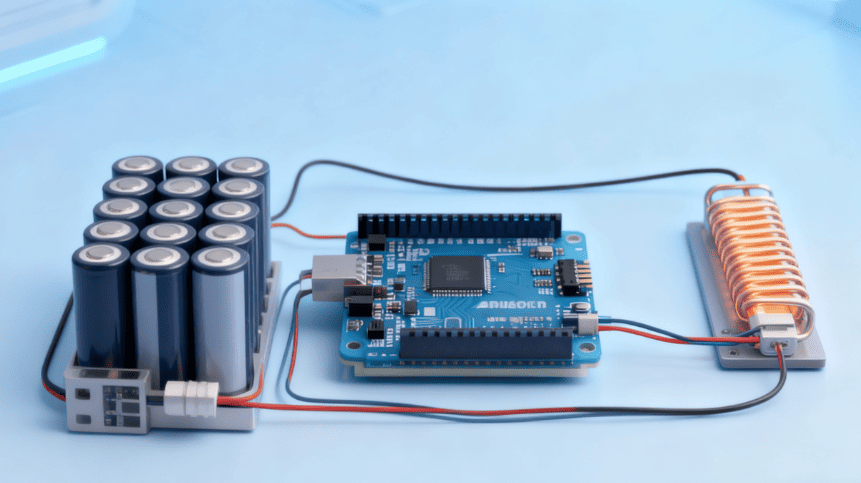

An effective solution involves a microcontroller-based system (such as an Arduino) combined with temperature sensors and heating elements.

Basic setup process:

-

Connect a temperature sensor (e.g., thermistor) and a heating element through a MOSFET or relay.

-

Program the Arduino to monitor the sensor reading.

-

Activate the heating element when the battery temperature drops below the set threshold.

-

Include a loop delay to prevent frequent switching and stabilize temperature control.

This setup allows for automated, real-time thermal management, ensuring batteries remain within the ideal range even during outdoor or industrial operations.

3. The Easiest and Most Practical Method: Insulation

Among all options, insulation remains the simplest and most efficient approach.

Battery blankets, in particular, outperform basic foam insulation because they:

-

Provide uniform temperature coverage

-

Minimize condensation risks

-

Offer durable, weather-resistant designs for field applications

For most users, a high-quality battery blanket provides the best balance between performance, cost, and convenience.

Conclusion

Maintaining lithium-ion battery warmth in cold environments is key to preserving capacity, efficiency, and lifespan.

Combine passive solutions (insulation, battery blankets, charge maintenance) with active temperature control systems for extreme conditions.

By keeping batteries within their 20°C–25°C optimal range, you ensure safe, stable, and reliable performance, whether powering electric vehicles, outdoor devices, or energy storage systems.

-

U.S. Department of Energy – Battery Performance in Cold Weather

-

Battery University – Charging and Discharging at Low Temperatures

-

Nature Energy – Advances in Lithium Battery Thermal Management

-

May.2026.02.27Lithium-Ion Batteries: The Six Constraints Blocking the Path to PerfectionLearn More

May.2026.02.27Lithium-Ion Batteries: The Six Constraints Blocking the Path to PerfectionLearn More -

May.2026.02.25Li-Polymer Battery 5000mAh: Complete Technical & OEM GuideLearn More

May.2026.02.25Li-Polymer Battery 5000mAh: Complete Technical & OEM GuideLearn More -

May.2026.02.24The Unparalleled Advantages of Lithium-Ion Batteries Over Traditional BatteriesLearn More

May.2026.02.24The Unparalleled Advantages of Lithium-Ion Batteries Over Traditional BatteriesLearn More -

May.2026.02.243.6 Volt Battery: Complete Technical Guide for Engineers & BuyersLearn More

May.2026.02.243.6 Volt Battery: Complete Technical Guide for Engineers & BuyersLearn More -

May.2026.02.24What Is a 3.8V LiPo Battery? A Complete Engineering & OEM GuideLearn More

May.2026.02.24What Is a 3.8V LiPo Battery? A Complete Engineering & OEM GuideLearn More