What Is Battery Pack?

Comprehensive Understanding of Battery Pack Technology

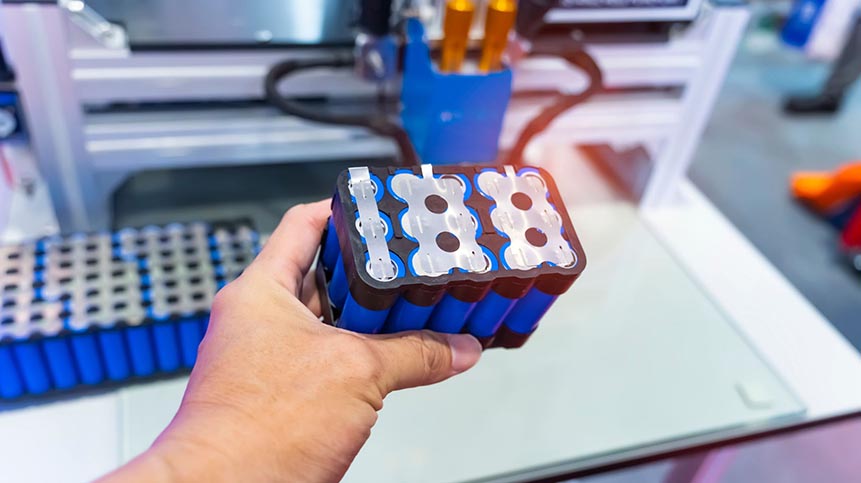

A battery pack represents a sophisticated assembly of multiple individual battery cells organized in specific configurations to deliver required voltage, capacity, and power characteristics for particular applications. Unlike single cells that provide limited voltage and capacity, battery packs integrate numerous cells with sophisticated management systems, protective circuitry, and mechanical housing to create complete energy storage solutions capable of powering everything from portable electronics to electric vehicles and grid-scale energy storage systems. The global battery pack market has experienced remarkable growth, reaching approximately $85 billion in 2023 and projected to exceed $200 billion by 2030, driven primarily by accelerating electric vehicle adoption, expanding renewable energy storage requirements, and continuous proliferation of portable electronic devices. This growth reflects the fundamental importance of battery packs in enabling the transition toward electrification and sustainable energy solutions across multiple sectors and applications worldwide.

The complexity of modern battery packs extends far beyond simple cell connections, incorporating advanced battery management systems (BMS), thermal management components, safety mechanisms, and communication interfaces that collectively ensure optimal performance, safety, and longevity. These integrated systems monitor and control numerous parameters including voltage, current, temperature, and state of charge while protecting against potentially hazardous conditions including overcharging, over-discharging, short circuits, and thermal runaway. The design and manufacturing of battery packs require multidisciplinary expertise spanning electrochemistry, electrical engineering, mechanical engineering, and software development to create products that meet increasingly demanding performance requirements and safety standards across diverse operating conditions and application environments.

Fundamental Components and Architecture

Cell Configuration and Electrical Architecture

The core of any battery pack consists of multiple individual cells connected in specific configurations to achieve desired electrical characteristics including voltage, capacity, and power capability. Series connections increase the overall voltage of the pack while maintaining the same capacity as individual cells, allowing the system to meet voltage requirements of various applications without requiring voltage conversion that would reduce efficiency. Parallel connections increase the overall capacity and current capability while maintaining the same voltage as individual cells, enabling longer runtime and higher power delivery without increasing voltage beyond application limits. Most practical battery packs utilize combinations of series and parallel connections to achieve both required voltage and capacity specifications, creating complex electrical architectures that must be carefully balanced to ensure optimal performance and longevity.

The electrical architecture extends beyond simple cell interconnections to include sensing wires that monitor individual cell or module voltages, current sensors that measure overall pack current, and temperature sensors distributed throughout the pack to monitor thermal conditions. These sensors connect to the battery management system, which continuously monitors all parameters and makes decisions regarding charging, discharging, and safety protection based on programmed algorithms and real-time conditions. The precision of these measurements and the sophistication of the control algorithms significantly influence the performance, safety, and lifespan of the battery pack, making the electrical architecture a critical aspect of overall pack design that requires careful consideration during the development process.

Battery Management System and Protection Circuitry

The battery management system (BMS) serves as the intelligent control center of the battery pack, performing numerous critical functions that ensure safe and efficient operation across diverse conditions. Advanced BMS implementations monitor each individual cell's voltage, temperature, and sometimes internal impedance, using this data to calculate precise state of charge (SOC), state of health (SOH), and state of power (SOP) estimations that inform operational decisions and provide user information. The system actively balances cells during charging to compensate for minor differences in capacity and self-discharge rates that would otherwise lead to progressive capacity loss and potential safety issues over time. This balancing function proves particularly important as packs age and cells inevitably diverge in their characteristics due to manufacturing variations and usage patterns.

Protection circuitry represents another crucial BMS function, continuously monitoring for potentially dangerous conditions including overvoltage, undervoltage, overcurrent, short circuits, and temperature extremes. When such conditions are detected, the BMS initiates protective actions including disconnecting the pack from loads or chargers, reducing maximum current limits, or activating thermal management systems to maintain safe operating conditions. More sophisticated BMS implementations incorporate predictive capabilities that anticipate potential issues before they become critical, adjusting operational parameters proactively to prevent hazardous situations rather than simply reacting to them after detection. These protection functions have become increasingly important as battery packs grow larger and more powerful, with potential failure consequences becoming more severe in high-energy applications including electric vehicles and grid storage systems.

Mechanical Structure and Thermal Management

Enclosure Design and Mechanical Integration

The mechanical structure of a battery pack provides physical protection for the cells and electronic components while ensuring proper alignment, connection, and integration with the host device or vehicle. Enclosure designs vary significantly based on application requirements, ranging from lightweight plastic housings for consumer electronics to massive welded aluminum enclosures for electric vehicles that provide structural rigidity and crash protection in addition to containing the battery components. The mechanical design must address numerous considerations including vibration resistance, shock absorption, environmental sealing, thermal management, serviceability, and manufacturability, often requiring sophisticated engineering analysis and prototyping to optimize all parameters simultaneously.

The integration of cells within the mechanical structure typically utilizes specialized holders, adhesives, or compression systems that maintain proper positioning while accommodating dimensional changes that occur during cycling and aging. These mechanical interfaces must provide sufficient pressure to ensure good electrical contact between cells and busbars while avoiding excessive force that could damage cells or cause internal short circuits. The design also incorporates provisions for thermal expansion, cell swelling over time, and potential replacement of individual components depending on the intended service life and maintenance philosophy of the product. The mechanical structure ultimately represents a critical compromise between protection, weight, volume, cost, and manufacturability that significantly influences the overall performance and commercial viability of the battery pack.

Thermal Management Systems

Effective thermal management represents one of the most critical aspects of battery pack design, directly influencing performance, safety, and lifespan across diverse operating conditions. Lithium-ion cells generate heat during both charging and discharging operations, with heat generation rates increasing significantly at higher currents and extreme temperatures. Without proper thermal management, this heat can accumulate unevenly within the pack, creating hot spots that accelerate degradation and potentially lead to thermal runaway conditions where increasing temperature causes further heat generation in a dangerous feedback loop. Thermal management systems aim to maintain cells within their optimal temperature range (typically 15-35°C) while minimizing temperature gradients across the pack to ensure uniform aging and performance.

Active thermal management systems utilize liquid cooling plates, refrigeration cycles, or forced air circulation to remove heat from cells, often incorporating heating elements for cold weather operation to maintain performance in low-temperature environments. These systems provide precise temperature control but add complexity, cost, and weight while consuming some of the pack's energy for their operation. Passive thermal management relies on thermal mass, phase change materials, or carefully designed natural convection paths to moderate temperature without consuming additional energy, though with less precise control capabilities. Most high-performance applications utilize active systems despite their disadvantages because the performance and lifespan benefits outweigh the additional complexity, particularly in automotive and grid storage applications where reliability and longevity are paramount considerations.

Table: Battery Pack Market Analysis by Application Segment

| Application Segment | 2023 Market Size ($ Billion) | 2030 Projected Market Size ($ Billion) | Compound Annual Growth Rate | Key Characteristics |

|---|---|---|---|---|

| Consumer Electronics | 28.5 | 45.2 | 7.8% | Compact size, high energy density, safety focus |

| Electric Vehicles | 38.7 | 125.4 | 18.3% | High power, advanced thermal management, safety systems |

| Energy Storage Systems | 12.3 | 42.8 | 19.5% | Long cycle life, cost efficiency, scalability |

| Industrial Equipment | 5.2 | 12.6 | 13.5% | Robust construction, wide temperature range, reliability |

| Medical Devices | 2.3 | 4.8 | 11.1% | Safety-critical, regulatory compliance, reliability |

Performance Parameters and Specifications

Electrical Performance Characteristics

Battery packs are specified according to numerous electrical parameters that determine their suitability for particular applications and operating conditions. Voltage specifications include nominal voltage (typical operating voltage), maximum voltage (fully charged condition), and minimum voltage (discharge cutoff), with the relationship between these values influencing the available energy utilization and efficiency. Capacity ratings indicate the total electrical charge stored in the pack, typically measured in ampere-hours (Ah) or milliampere-hours (mAh), though the actual usable capacity depends on discharge rate, temperature, age, and cutoff voltage settings. Energy content represents the total stored energy calculated as voltage multiplied by capacity, measured in watt-hours (Wh) or kilowatt-hours (kWh), providing a more application-relevant metric than capacity alone.

Power capability indicates how quickly the pack can deliver or accept energy, typically specified as maximum continuous and peak discharge currents or power levels, with these parameters often limited by internal resistance and thermal considerations rather than absolute energy content. Internal resistance affects voltage sag under load, efficiency, heat generation, and overall performance, with lower resistance generally indicating better performance characteristics particularly for high-power applications. Efficiency metrics include coulombic efficiency (ratio of discharge capacity to charge capacity) and energy efficiency (ratio of discharge energy to charge energy), both of which vary with operating conditions and influence the overall effectiveness of the energy storage system. These electrical parameters collectively define the fundamental performance capabilities of the battery pack and must be carefully matched to application requirements during the selection or design process.

Safety and Reliability Specifications

Safety represents a paramount consideration in battery pack design and specification, with numerous standards and regulations governing various aspects of construction, performance, and testing. Safety specifications typically include requirements for electrical protection (overcharge, over-discharge, overcurrent, short circuit), mechanical protection (vibration, shock, crush, drop), environmental protection (temperature, humidity, altitude), and failure containment (thermal runaway propagation prevention). Regulatory compliance often requires testing and certification according to international standards including UL, IEC, UN, and various regional regulations that continue to evolve as battery technology advances and new applications emerge. These safety requirements significantly influence pack design, component selection, and manufacturing processes, often adding cost and complexity but providing essential protection against potential hazards.

Reliability specifications address the long-term performance and durability of the battery pack under expected operating conditions, typically including cycle life (number of charge-discharge cycles before significant capacity loss), calendar life (total service life regardless of usage), and performance retention under various environmental conditions. Accelerated testing methods predict long-term performance based on shorter-term testing under stressed conditions, though correlating these accelerated results to real-world performance remains challenging due to the complex degradation mechanisms involved. Reliability engineering considers numerous factors including component selection, design margins, manufacturing processes, and operational parameters to create packs that meet lifespan expectations across diverse usage scenarios and environmental conditions. These reliability considerations prove particularly important for applications where battery replacement is difficult or expensive, including embedded systems, electric vehicles, and grid storage installations.

Application-Specific Design Considerations

Consumer Electronics Applications

Battery packs for consumer electronics prioritize energy density, form factor, and safety while meeting cost targets for highly competitive markets. Smartphone battery packs typically utilize high-energy-density lithium-ion or lithium-polymer cells in sophisticated multi-layer pouches that maximize capacity within strict dimensional constraints, often incorporating advanced battery management systems that optimize charging protocols based on usage patterns and extend lifespan through careful voltage control. These packs face challenging requirements including high discharge rates for processor-intensive applications, rapid charging capabilities, and exceptional safety reliability given their proximity to users in daily life. The design process involves close collaboration between device manufacturers and battery suppliers to optimize the pack specifically for each device model, balancing performance, size, cost, and safety through iterative development and extensive testing.

Laptop battery packs present different challenges with higher capacity requirements, more complex multi-cell arrangements, and sophisticated power management systems that interface with the computer's operating system to provide runtime predictions and health status information. These packs often incorporate 3-6 cells in series configurations to achieve required voltages, with precision monitoring and balancing circuits that ensure optimal performance and safety throughout years of daily use. The increasing performance demands of modern computers, including high-power processors and bright displays, require packs capable of delivering substantial power while maintaining stable voltage and efficient operation. Consumer electronics battery packs represent some of the most advanced mass-produced energy storage systems, incorporating cutting-edge cell technologies, sophisticated management systems, and precision manufacturing processes to meet demanding market requirements.

Electric Vehicle Applications

Electric vehicle battery packs represent the most complex and demanding application for current battery technology, requiring exceptional energy density, power capability, safety, and longevity under challenging operating conditions. These packs typically contain thousands of individual cells arranged in complex series-parallel configurations to achieve voltages of 400-800V and capacities of 60-100 kWh or more for modern electric vehicles. The design incorporates comprehensive safety systems including crash protection, intrusion detection, multiple redundant isolation monitoring, and sophisticated thermal runaway containment systems that prevent propagation if individual cells fail. The battery management system in electric vehicle packs represents the most advanced implementation of monitoring and control technology, with capabilities extending beyond basic protection to include state estimation, thermal management control, charging optimization, and communication with vehicle systems.

The mechanical design of electric vehicle battery packs integrates with the vehicle structure, often serving as a structural element that contributes to overall rigidity and crash safety while protecting the cells from impact damage. Thermal management systems typically utilize liquid cooling plates with precise temperature control to maintain optimal conditions during driving and charging, with heating capabilities for cold weather operation to preserve performance and charging capability. The design process involves extensive simulation, prototyping, and testing to validate performance and safety under extreme conditions, with validation procedures far exceeding those for consumer electronics applications due to the safety-critical nature of automotive systems. Electric vehicle battery packs represent the cutting edge of battery technology, incorporating advancements in cells, electronics, thermal management, and safety systems that continue to evolve rapidly as the industry accelerates toward electrification.

Manufacturing Processes and Quality Control

Production Methodologies and Automation

The manufacturing of battery packs involves numerous processes that transform individual cells, electronic components, and mechanical parts into complete functional systems meeting precise specifications. Modern battery pack production utilizes increasingly automated assembly lines that handle cell sorting and matching, interconnection welding or soldering, component placement, and final assembly with minimal human intervention to ensure consistency and quality. The manufacturing process typically begins with cell testing and characterization to identify and group cells with similar characteristics, ensuring balanced performance within each pack and minimizing variations between production units. Automated equipment then assembles cells into modules or direct pack configurations, installing interconnections, sensors, and preliminary wiring before integrating the battery management system and protection circuitry.

Advanced manufacturing facilities incorporate sophisticated quality control systems including automated optical inspection, electrical testing at multiple stages, and traceability systems that track each component throughout the production process. These systems ensure that any issues can be quickly identified and addressed while providing data for continuous process improvement and quality enhancement. The final assembly stages include enclosure installation, sealing for environmental protection, and comprehensive functional testing that verifies all electrical, safety, and communication functions operate correctly before packs are prepared for shipment. The manufacturing process represents a critical determinant of final pack quality, reliability, and cost, with leading manufacturers continuously investing in advanced automation, process control, and quality assurance systems to maintain competitiveness in increasingly demanding markets.

Quality Assurance and Testing Protocols

Quality assurance in battery pack manufacturing involves extensive testing at multiple stages from incoming materials to final products, with protocols designed to ensure safety, performance, and reliability across expected operating conditions. Incoming component inspection includes verification of cell specifications, electronic component functionality, and material properties to ensure all materials meet design requirements before entering production. During assembly, in-process testing checks electrical connections, sensor functionality, and basic operational parameters to identify issues early in the manufacturing process when correction is most efficient. Final testing represents the most comprehensive evaluation, typically including electrical performance verification, safety system validation, environmental testing, and sometimes accelerated life testing to predict long-term reliability.

Safety testing protocols subject finished packs to extreme conditions beyond normal operating limits to verify that protection systems function correctly and hazardous situations are prevented. These tests include overcharge, over-discharge, short circuit, thermal abuse, mechanical abuse, and environmental exposure scenarios that simulate potential misuse or accident conditions. Performance testing characterizes electrical parameters including capacity, efficiency, internal resistance, and temperature behavior across the intended operating range, ensuring packs meet specification requirements before delivery to customers. Reliability testing uses accelerated aging methods including elevated temperature operation, rapid cycling, and vibration exposure to predict long-term performance and identify potential failure modes before products reach the market. These comprehensive testing protocols ensure that battery packs meet the increasingly stringent requirements of modern applications where performance, safety, and reliability are critical considerations for end users.

Future Trends and Technological Evolution

Advanced Materials and Cell Technologies

The ongoing evolution of battery pack technology continues to leverage advancements in cell chemistries, materials, and manufacturing processes that enhance performance, reduce cost, and improve sustainability. Solid-state battery technology represents perhaps the most significant upcoming advancement, potentially offering higher energy density, improved safety, and longer lifespan compared to current lithium-ion technologies. These systems replace flammable liquid electrolytes with solid alternatives that eliminate combustion risks while enabling lithium metal anodes that significantly increase energy density. While still primarily in development and early commercialization stages, solid-state batteries promise to enable new pack designs with simplified thermal management requirements and potentially reduced safety system complexity due to their inherent stability.

Advanced lithium-ion chemistries continue to evolve with higher nickel content cathodes, silicon-composite anodes, and improved electrolyte formulations that incrementally enhance energy density, power capability, and cycle life. These gradual improvements allow pack designers to increase performance within existing form factors and design paradigms while maintaining compatibility with established manufacturing processes and infrastructure. Beyond chemical improvements, structural battery concepts that integrate energy storage directly into product structures promise to revolutionize pack design by eliminating separate battery enclosures and more efficiently utilizing available space. These innovative approaches could particularly benefit weight-sensitive applications including electric aviation and portable electronics where energy density and form factor represent critical design constraints.

Intelligent Systems and Connectivity

The integration of intelligence and connectivity represents another significant trend in battery pack evolution, transforming passive energy storage devices into active system components that optimize their own operation and communicate with other system elements. Advanced battery management systems increasingly incorporate artificial intelligence and machine learning algorithms that adapt to usage patterns, predict remaining useful life, and optimize charging strategies based on individual user behavior and future requirements. These intelligent systems can significantly extend battery lifespan by avoiding stressful operating conditions, balancing cells more effectively, and providing maintenance recommendations before issues become critical.

Connectivity features enable remote monitoring, diagnostics, and management of battery packs across diverse applications from consumer electronics to grid storage systems. Cloud-connected battery management systems can aggregate operational data from numerous packs in the field, using this information to improve future designs, identify potential issues before they cause failures, and optimize overall system performance based on real-world usage patterns. These capabilities prove particularly valuable for large-scale deployments including electric vehicle fleets and grid storage installations where centralized management and optimization can significantly improve economics and reliability. The evolution toward increasingly intelligent and connected battery packs represents a natural progression as computing capability becomes more affordable and energy storage systems play increasingly critical roles in both personal devices and larger infrastructure applications.

-

May.2025.12.22What is a Nickel Cadmium Battery and How Does It WorkLearn More

May.2025.12.22What is a Nickel Cadmium Battery and How Does It WorkLearn More -

May.2025.12.22How to clean battery corrosion?Learn More

May.2025.12.22How to clean battery corrosion?Learn More -

May.2025.12.2021700 Battery: Meaning, Comparison with 18650, and How to Choose the Best QualityLearn More

May.2025.12.2021700 Battery: Meaning, Comparison with 18650, and How to Choose the Best QualityLearn More -

May.2025.12.19Medical Device 18650 Rechargeable Battery: What Buyers Must Evaluate?Learn More

May.2025.12.19Medical Device 18650 Rechargeable Battery: What Buyers Must Evaluate?Learn More -

May.2025.12.19Common voltage types of lithium polymer batteries for different applicationsLearn More

May.2025.12.19Common voltage types of lithium polymer batteries for different applicationsLearn More