Battery Certification Guide: Process, Timeline & The Value of an Expert Partner

Navigating the complex landscape of battery certification is a mandatory step for global market entry. Certification validates safety, reliability, and compliance, ensuring products meet international standards. This guide outlines the certification journey and highlights the benefits of partnering with an experienced supplier.

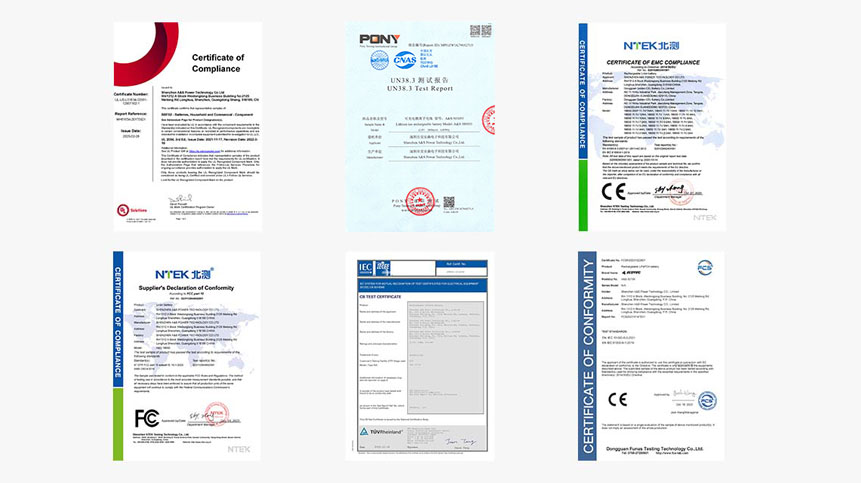

The Value of a Certified & Experienced Battery Partner

A proven supplier with a strong portfolio of certifications transforms the certification journey from a hurdle into a predictable, managed process.

-

Culture of Quality: Certifications such as ISO 9001 and IATF 16949 prove systematic commitment to quality.

-

Compliance with Standards: Meeting IEC 62133 and UL 2054 drastically reduces risk.

-

Customization Without Compromise: Expert partners design for both innovation and compliance, improving first-pass success rates and accelerating market entry.

The Three-Phase Certification Framework

The battery certification process follows a structured three-phase journey:

Phase 1: Planning & Preparation (≈20% of Time)

-

Define target markets and required standards (EU, USA, etc.).

-

Select an accredited certification body (e.g., TÜV, UL).

-

Conduct gap analysis of product design.

-

Prepare prototypes for submission.

Mistakes here can cause costly redesigns later.

Phase 2: Testing, Audit & Certification (≈50% of Time)

-

Mandatory UN 38.3 testing for transport safety.

-

Safety & performance tests (e.g., overcharge, short circuit, crush).

-

Factory audits for production verification.

-

Certification Body issues a Certificate of Compliance (CoC) if tests are passed.

First-Time Pass Rate is critical — failures add significant time.

Phase 3: Maintenance & Compliance (Ongoing)

-

Annual surveillance audits.

-

Strict approval for any design changes.

-

Compliance with market surveillance spot-checks to avoid penalties and recalls.

Realistic Battery Certification Timeline

Timelines vary depending on complexity, certification scope, and pass rates.

-

UN 38.3 (Transport only): 3–4 weeks.

-

Basic Safety (CB Scheme / IEC): 8–12 weeks.

-

Full UL Compliance (USA): 12–20+ weeks.

-

Multi-Market (EU + USA): 16–24+ weeks.

Key Recommendations for Success

-

Start Early: Integrate certification during the design stage (Design for Compliance).

-

Choose an Expert Partner: A supplier with a strong certification history minimizes risk.

-

Maintain Consistency: Ensure prototypes match mass production units.

-

Plan for Delays: Budget for re-testing and extended approval times.

Conclusion

Battery certification is a rigorous but essential process for safe, compliant, and reliable products. Partnering with an experienced supplier ensures smoother navigation, reduced risks, and faster entry into global markets.

-

May.2025.12.22What is a Nickel Cadmium Battery and How Does It WorkLearn More

May.2025.12.22What is a Nickel Cadmium Battery and How Does It WorkLearn More -

May.2025.12.22How to clean battery corrosion?Learn More

May.2025.12.22How to clean battery corrosion?Learn More -

May.2025.12.2021700 Battery: Meaning, Comparison with 18650, and How to Choose the Best QualityLearn More

May.2025.12.2021700 Battery: Meaning, Comparison with 18650, and How to Choose the Best QualityLearn More -

May.2025.12.19Medical Device 18650 Rechargeable Battery: What Buyers Must Evaluate?Learn More

May.2025.12.19Medical Device 18650 Rechargeable Battery: What Buyers Must Evaluate?Learn More -

May.2025.12.19Common voltage types of lithium polymer batteries for different applicationsLearn More

May.2025.12.19Common voltage types of lithium polymer batteries for different applicationsLearn More