14500 Battery vs AA Battery: A Complete Technical and Application Guide

Introduction: Why This Comparison Matters

As a battery manufacturer and customization provider, we often receive a very common question from engineers, product managers, and procurement teams:

“Can I replace an AA battery with a 14500 battery?”

At first glance, the confusion is understandable.

Both 14500 batteries and AA batteries share nearly the same physical dimensions. However, from an electrical, chemical, and safety perspective, they are fundamentally different power sources.

In this guide, I’ll walk you through a professional, real-world comparison of 14500 batteries vs AA batteries—covering voltage, capacity, discharge behavior, safety, compatibility, and practical application scenarios—so you can make the right technical and commercial decision.

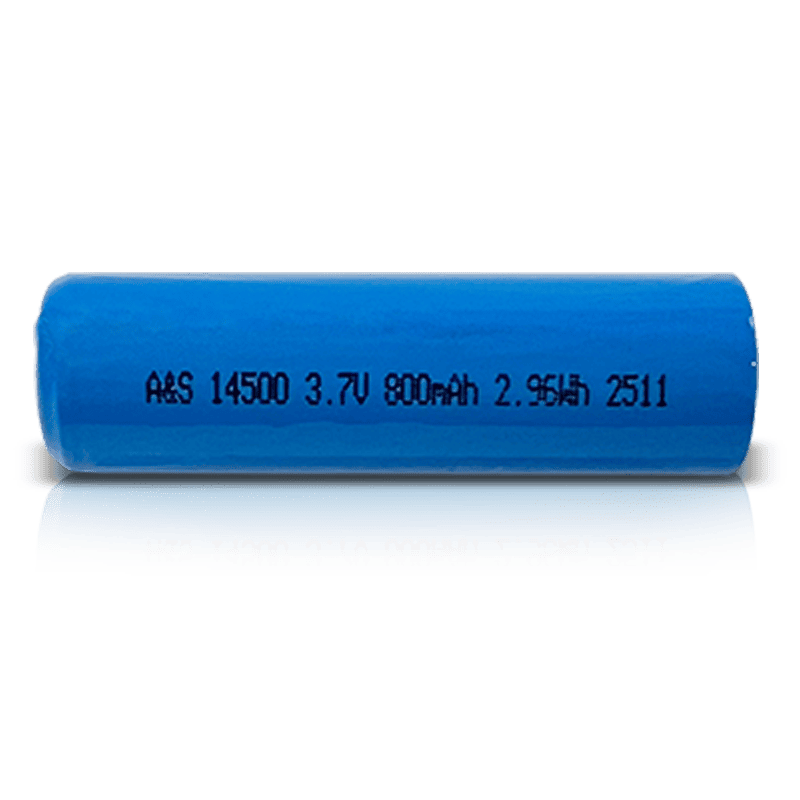

What Is a 14500 Battery?

A 14500 battery is a rechargeable lithium-ion battery with a cylindrical format measuring approximately 14 mm in diameter and 50 mm in length—hence the name 14500.

Key Characteristics of a 14500 Battery

-

Chemistry: Lithium-ion (Li-ion)

-

Nominal Voltage: 3.6V – 3.7V

-

Full Charge Voltage: 4.2V

-

Typical Capacity: 600–1000 mAh

-

Rechargeable: Yes

-

Protection: Often requires built-in or external protection circuitry

Unlike disposable AA batteries, a 14500 cell is designed for high energy density, stable output, and repeated charging cycles, making it suitable for modern electronic devices.

What Is an AA Battery?

An AA battery is one of the most widely used standard battery sizes in the world. Unlike 14500 cells, AA batteries come in multiple chemistries, each with different performance characteristics.

Common AA Battery Types

-

Alkaline AA (1.5V, non-rechargeable)

-

NiMH AA (1.2V, rechargeable)

-

Lithium Primary AA (1.5V, non-rechargeable)

Typical AA Battery Specs

-

Nominal Voltage: 1.2V – 1.5V

-

Capacity Range: 1800–3000 mAh (chemistry-dependent)

-

Energy Density: Lower than lithium-ion

-

Safety Level: Generally high due to lower voltage

AA batteries are optimized for low-to-moderate power devices and broad consumer compatibility.

14500 vs AA Battery: Core Technical Differences

Size Comparison (Same Form Factor, Different Power)

| Parameter | 14500 Battery | AA Battery |

|---|---|---|

| Diameter | ~14 mm | ~14 mm |

| Length | ~50 mm | ~50 mm |

| Physical Fit | Same | Same |

| Electrical Output | Very Different | Very Different |

Important:

Mechanical compatibility does not mean electrical compatibility.

Voltage Comparison (Critical Difference)

| Battery Type | Nominal Voltage | Max Voltage |

|---|---|---|

| 14500 Li-ion | 3.6–3.7V | 4.2V |

| Alkaline AA | 1.5V | ~1.6V |

| NiMH AA | 1.2V | ~1.4V |

➡ A 14500 battery outputs more than double the voltage of an AA battery.

This is the number one reason direct replacement is dangerous.

Capacity vs Energy (mAh Can Be Misleading)

| Battery | Typical Capacity | Nominal Energy |

|---|---|---|

| 14500 Li-ion | 800 mAh | ~3.0 Wh |

| Alkaline AA | 2500 mAh | ~3.75 Wh |

| NiMH AA | 2000 mAh | ~2.4 Wh |

While AA batteries often show higher mAh, the total energy (Wh) can be similar or even lower than a 14500 battery.

Can You Replace an AA Battery with a 14500 Battery?

Short answer: Not directly.

Long answer: Only if the device is specifically designed for it.

Why Direct Replacement Is Unsafe

-

Overvoltage damage to ICs

-

Overheating of motors or LEDs

-

PCB trace burnout

-

Fire or thermal runaway risk

When Replacement Is Possible

-

Device explicitly supports 3.7V input

-

Built-in voltage regulation

-

Designed for both AA and Li-ion variants

-

Manufacturer approval

Performance Comparison in Real Applications

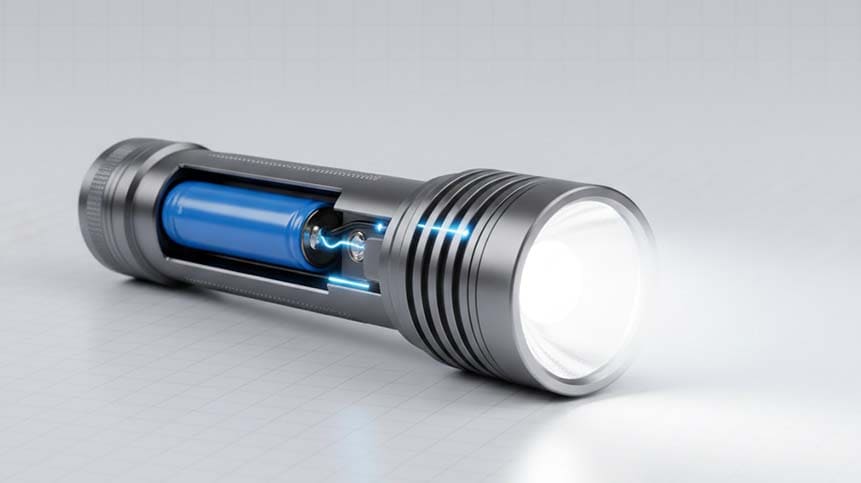

Flashlights

| Aspect | AA Battery | 14500 Battery |

|---|---|---|

| Brightness | Moderate | Very High |

| Runtime | Longer (low power) | Shorter at max output |

| Heat | Low | High |

| Compatibility | Universal | Device-specific |

Modern high-lumen flashlights increasingly support 14500 batteries for higher output.

Medical & Industrial Devices

For regulated electronics such as:

-

Medical monitors

-

Handheld diagnostic tools

-

Sensors and meters

AA batteries are often preferred for:

-

Lower voltage safety

-

Regulatory simplicity

-

Predictable discharge curves

However, custom 14500-based battery packs with proper BMS are increasingly used in OEM medical devices.

Safety Considerations: Lithium vs AA Batteries

14500 Battery Safety

-

Requires protection circuit (OVP, OCP, UVP)

-

Sensitive to overcharge and short circuits

-

Must use dedicated Li-ion chargers

AA Battery Safety

-

Lower voltage = lower risk

-

Alkaline leakage risk

-

NiMH safer but lower energy density

device-level safety design matters more than chemistry alone.

Charging and Lifecycle Comparison

| Factor | 14500 Li-ion | NiMH AA |

|---|---|---|

| Charge Cycles | 300–500 | 500–1000 |

| Self-discharge | Low | Moderate |

| Charging Speed | Fast | Moderate |

| Charger Type | Dedicated Li-ion | NiMH-specific |

Cost Analysis Over Product Lifecycle

| Cost Factor | AA Battery | 14500 Battery |

|---|---|---|

| Initial Cost | Low | Higher |

| Charger Cost | Optional | Required |

| Long-term Cost | High (disposable) | Lower (rechargeable) |

For OEM products, rechargeable 14500 solutions often reduce total cost of ownership.

Choosing the Right Battery: Professional Decision Framework

Ask these questions before selecting:

-

What input voltage does the circuit tolerate?

-

Is the device regulated or unregulated?

-

Safety certification requirements?

-

Disposable vs rechargeable strategy?

-

End-user charging behavior?

If voltage tolerance is unclear, default to AA batteries or consult a battery engineer.

Custom Battery Solutions: Beyond Standard AA and 14500

In many projects, neither standard AA nor off-the-shelf 14500 cells are ideal.

Custom options include:

-

14500 with PCM protection

-

Series/parallel battery packs

-

Custom connectors and housings

-

UL / IEC / UN38.3 certified assemblies

? If your product requires stable 3.7V output, a custom 14500 lithium battery pack is often the safest and most efficient solution.

FAQ – 14500 Battery vs AA Battery

Q1: Is a 14500 battery the same size as AA?

Yes, physically similar—but electrically very different.

Q2: Will a 14500 battery damage an AA device?

In most cases, yes, due to higher voltage.

Q3: Which battery lasts longer?

Depends on load, regulation, and usage profile.

Q4: Are 14500 batteries safer than AA?

Safe when properly protected; unsafe if misused.

Q5: Can I use AA chargers for 14500 batteries?

No. Never mix charger types.

-

May.2026.01.23Lithium LiPo Battery for Internet of Things (IoT) and Smart HardwareLearn More

May.2026.01.23Lithium LiPo Battery for Internet of Things (IoT) and Smart HardwareLearn More -

May.2026.01.22Lithium LiPo Battery for Medical and Health Monitoring EquipmentLearn More

May.2026.01.22Lithium LiPo Battery for Medical and Health Monitoring EquipmentLearn More -

May.2026.01.22Lithium LiPo Battery for Beauty Products (K-Beauty & Beyond)Learn More

May.2026.01.22Lithium LiPo Battery for Beauty Products (K-Beauty & Beyond)Learn More -

May.2026.01.22Lithium LiPo Battery for Portable Consumer Electronic DevicesLearn More

May.2026.01.22Lithium LiPo Battery for Portable Consumer Electronic DevicesLearn More -

May.2026.01.2114500 Battery vs AA Battery: A Complete Technical and Application GuideLearn More

May.2026.01.2114500 Battery vs AA Battery: A Complete Technical and Application GuideLearn More