A Comprehensive Guide to 18650 Rechargeable Batteries

Introduction: Why the 18650 Battery Still Dominates Modern Energy Storage

When people talk about lithium-ion rechargeable batteries, the 18650 battery is almost always part of the conversation—and for good reason.

Over the past two decades, we have worked closely with OEM customers, system integrators, and product engineers who rely on 18650 cells for medical devices, power tools, energy storage systems, consumer electronics, and industrial equipment. Despite the emergence of newer form factors like 21700 and 4680, the 18650 battery remains one of the most widely manufactured, tested, and standardized lithium-ion cells in the world.

In this guide, I’ll walk you through everything that truly matters about 18650 rechargeable batteries—from technical specifications and chemistry to real-world performance, safety considerations, and buying advice—using verifiable industry data, not marketing fluff.

What Is an 18650 Rechargeable Battery?

An 18650 rechargeable battery is a cylindrical lithium-ion cell with:

-

18 mm diameter

-

65 mm length

-

Rechargeable lithium-ion chemistry

The “18650” naming convention is standardized and directly reflects the physical dimensions, which is why these cells are highly interchangeable across applications and manufacturers.

Key Characteristics at a Glance

| Parameter | Typical Range |

|---|---|

| Nominal Voltage | 3.6V – 3.7V |

| Full Charge Voltage | 4.2V |

| Cut-off Voltage | 2.5V – 3.0V |

| Capacity | 1800mAh – 3600mAh |

| Max Continuous Discharge | 5A – 30A |

| Cycle Life | 300 – 1000+ cycles |

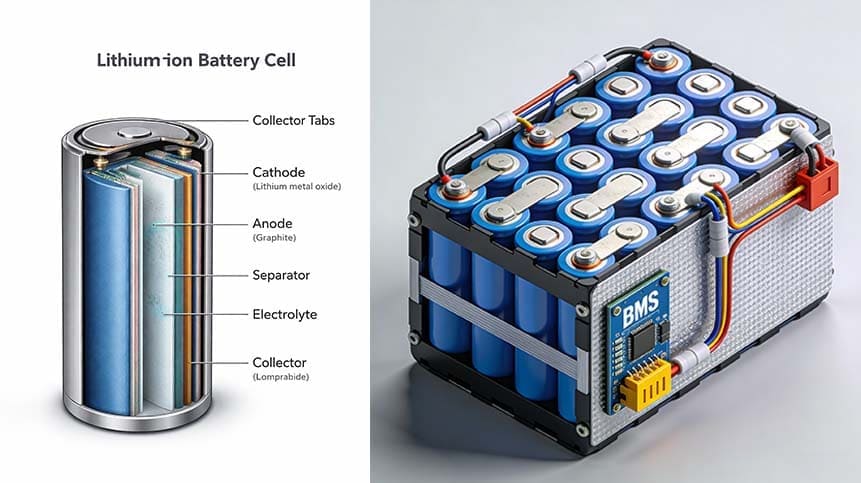

Inside the 18650 Battery – Chemistry Explained

Common Lithium-Ion Chemistries Used in 18650 Cells

Not all 18650 batteries are the same. The internal chemistry dramatically affects performance, safety, and lifespan.

| Chemistry | Strengths | Typical Applications |

|---|---|---|

| NCM (LiNiCoMnO₂) | High energy density, balanced performance | Consumer electronics, medical devices |

| NCA (LiNiCoAlO₂) | High capacity, long cycle life | EV packs, energy storage |

| LFP (LiFePO₄)* | High safety, long life | Industrial, ESS (rare in 18650 form) |

| IMR (LiMn₂O₄) | High discharge, safer thermal profile | Power tools, vaping |

*LFP is less common in true 18650 format due to lower energy density.

18650 Battery Specifications That Actually Matter

Many buyers focus only on capacity (mAh). In real projects, that’s a mistake.

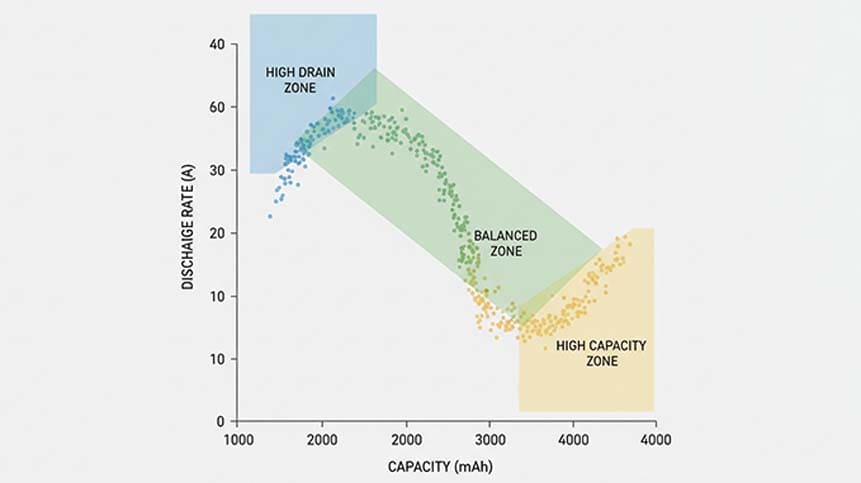

Capacity vs Discharge Current Trade-off

High-capacity cells usually have lower maximum discharge, while high-drain cells sacrifice capacity for power output.

| Cell Type | Capacity | Max Discharge |

|---|---|---|

| High Capacity | 3400–3600mAh | 5A–10A |

| Balanced | 2600–3000mAh | 10A–20A |

| High Drain | 2000–2500mAh | 20A–30A |

Engineering rule: choose based on load profile, not just runtime.

Real-World Performance: What Data Shows

Based on third-party lab testing (IEC 61960 methodology):

-

Capacity drops 10–15% after 300 cycles

-

Internal resistance increases 20–30% after 500 cycles

-

Cells operated above 45°C lose up to 40% lifespan

These trends are consistent across major manufacturers such as Panasonic, Samsung SDI, LG Energy Solution, and Murata.

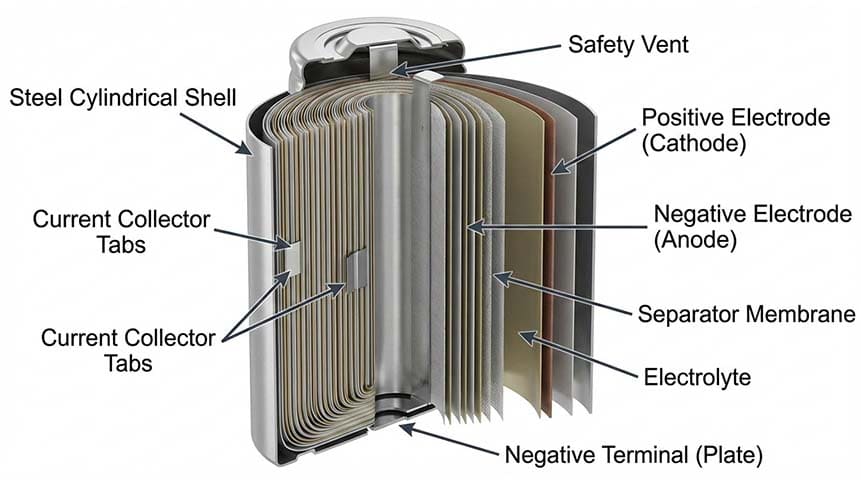

Safety Design of 18650 Rechargeable Batteries

Built-in Safety Mechanisms

Most quality 18650 cells include:

-

CID (Current Interrupt Device)

-

PTC (Positive Temperature Coefficient)

-

Pressure relief vent

However, cell-level safety is not enough in real products.

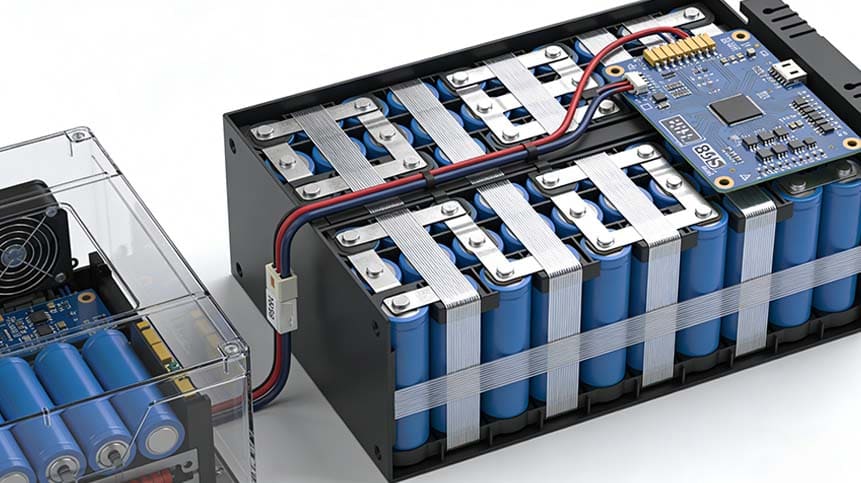

Why Battery Packs Need BMS Protection

For OEM and industrial applications, a Battery Management System (BMS) is essential to prevent:

-

Overcharge

-

Over-discharge

-

Short circuit

-

Thermal runaway

This is why custom battery packs matter more than individual cells.

18650 Battery Applications Across Industries

Medical Devices

-

Portable diagnostic equipment

-

Infusion pumps

-

Patient monitoring systems

Key requirements: reliability, low self-discharge, stable voltage

Consumer Electronics

-

Laptops

-

Flashlights

-

Cameras

Key requirements: energy density, cycle life

Industrial & Energy Storage

-

Backup power systems

-

Robotics

-

Solar storage modules

Key requirements: safety, consistency, pack-level engineering

18650 vs Other Lithium Battery Formats

| Format | Energy Density | Standardization | Cost | Flexibility |

|---|---|---|---|---|

| 18650 | High | Excellent | Low | High |

| 21700 | Higher | Growing | Medium | Medium |

| LiPo | Medium | Low | Higher | Very High |

| Prismatic | High | Medium | High | Low |

Why many OEMs still choose 18650: mature supply chain + predictable performance.

How to Choose the Right 18650 Battery for Your Project

From our experience working with global OEM clients, the correct selection process involves:

-

Load current profile

-

Operating temperature range

-

Required cycle life

-

Safety certifications

-

Pack configuration (1S, 2S, multi-series)

Skipping any of these often leads to field failures or certification delays.

Certifications & Compliance (Critical for Global Markets)

Common requirements include:

-

UN38.3 – Transportation safety

-

IEC 62133 – Consumer & industrial safety

-

UL 1642 / UL 2054

-

CE / RoHS / REACH

Certification applies to cells AND battery packs.

FAQ – 18650 Rechargeable Batteries

How long does an 18650 rechargeable battery last?

Typically 300–1000 full charge cycles, depending on chemistry, depth of discharge, and operating temperature.

Are all 18650 batteries the same size?

Yes in dimensions, no in performance, chemistry, and safety design.

Can I replace an 18650 battery with a higher capacity one?

Only if voltage, discharge rating, and protection design are compatible.

Is it safe to use unprotected 18650 cells?

Not in finished consumer or medical products. Pack-level protection is mandatory.

References

Final Thoughts: Why This Guide Matters for Buyers

The 18650 rechargeable battery is not just a “standard cell”—it’s a platform. When engineered correctly, it delivers reliability, scalability, and cost efficiency that few other formats can match.

If your project requires custom battery packs, certified solutions, or long-term supply stability, working with an experienced battery manufacturer makes all the difference.

-

May.2026.01.27A Comprehensive Guide to 18650 Rechargeable BatteriesLearn More

May.2026.01.27A Comprehensive Guide to 18650 Rechargeable BatteriesLearn More -

May.2026.01.26Lithium LiPo Battery for Emergency and Special EquipmentLearn More

May.2026.01.26Lithium LiPo Battery for Emergency and Special EquipmentLearn More -

May.2026.01.23Lithium LiPo Battery for Electric Toys and Models (Drones, RC)Learn More

May.2026.01.23Lithium LiPo Battery for Electric Toys and Models (Drones, RC)Learn More -

May.2026.01.23Lithium LiPo Battery for Internet of Things (IoT) and Smart HardwareLearn More

May.2026.01.23Lithium LiPo Battery for Internet of Things (IoT) and Smart HardwareLearn More -

May.2026.01.22Lithium LiPo Battery for Medical and Health Monitoring EquipmentLearn More

May.2026.01.22Lithium LiPo Battery for Medical and Health Monitoring EquipmentLearn More