7.4V LiPo Battery — A Practical Guide (2S Li-Po / 7.4V)

Introduction — why I wrote this

I work with battery systems every day and I wrote this guide to help engineers, procurement teams and product managers quickly understand what a 7.4V LiPo (2S) pack is, how to evaluate specs, calculate run time, and choose a safe, optimized battery for their application. This guide blends practical formulas, manufacturer-style specs and safety best practices so you can make faster buying and design decisions — and confidently request quotes.

What is a 7.4V LiPo battery?

A 7.4V LiPo battery is typically a 2-cell (2S) lithium-polymer pack where each cell has a nominal voltage ~3.7V, giving a nominal pack voltage ≈ 7.4V. Cell charge limits are commonly 4.2V per cell (fully charged) and recommended cut-off is generally near 3.0V per cell to avoid damage. These voltages and charging guidance are standard across the industry.

Typical pack configurations and connectors

-

Cell count: 2S1P (2 cells in series) is the usual configuration for 7.4V packs.

-

Capacities: common mAh ratings range from a few hundred mAh (micro RC) up to 6,000+ mAh for radios and larger systems. Example product pages show 700mAh, 800mAh, 3000mAh and 6200mAh variants.

-

Connectors: JST, JST-XH, XT30, EC2, XT60 (for higher current) — choose based on discharge current and mechanical needs.

Key technical specs explained

Nominal voltage and full-charge voltage

-

Nominal pack voltage = 7.4V (2 × 3.7V).

-

Full-charge voltage = 8.4V (2 × 4.2V).

These are fundamental for matching power electronics and chargers.

Capacity (mAh) and energy (Wh)

-

Capacity in mAh (milliamp-hours) tells how much charge the pack stores.

-

Watt-hours (Wh) = (mAh/1000) × Nominal Voltage (7.4V). Use Wh when comparing energy across voltages or when calculating device run-time in watts. See table below.

C-rating (discharge rate)

-

The “C” rating indicates the safe continuous discharge multiple of capacity. Example: a 25C 800mAh pack can theoretically supply 0.8Ah × 25 = 20A continuous. Always match the motor/driver peak and continuous current needs with conservative margin. Manufacturer pages list C ratings for RC/drone packs.

Charge rate (max charging current)

-

Max recommended charge is often 1C to 3C depending on cell construction. Always follow the manufacturer’s data and use balance chargers. Charging protocols and balance rules are crucial for safety and longevity.

Safety and handling (must-read)

LiPo packs provide excellent energy density but require careful handling. Key safety practices I follow and recommend:

-

Use a proper balance charger and never exceed recommended charge voltage (4.2V per cell). Balance charging keeps cells at equal voltages and extends pack life.

-

Do not leave batteries unattended while charging; many incidents occur during charging. Charge on a non-combustible surface and consider a LiPo charging bag for added safety.

-

Avoid over-discharge: stop using a pack at or above the manufacturer-recommended per-cell cutoff (commonly ~3.0V). Over-discharge can permanently degrade cells.

-

Inspect packs regularly for puffing (swelling), heat, or damaged pouches — dispose safely if damaged.

Why I stress this: most LiPo-related fires are linked to charging, physical damage, or misuse. Following simple discipline reduces risk dramatically.

Run-time & capacity calculations

How I calculate run time

Two practical formulas I use:

-

If you know device power (W):

Run time (hours) = Battery Wh ÷ Device power (W), where Wh = (mAh ÷ 1000) × 7.4. -

If you know average current draw (A):

Run time (hours) = Capacity (Ah) ÷ Current draw (A) (multiply by 60 for minutes). This is common for brushless motors & RC applications.

Practical examples (table)

Below are calculated examples using nominal voltage 7.4V. These illustrate theoretical run times — expect 70–90% usable capacity in real applications after accounting for inverter loss, regulator inefficiency, altitude/temperature effects and C-rate losses.

|

Pack capacity (mAh)

|

Energy (Wh)

|

Run time @ 5W (hrs)

|

Run time @ 20W (hrs)

|

Run time @ 50W (hrs)

|

|---|---|---|---|---|

| 800 mAh | 5.92 Wh | 1.18 h | 0.30 h | 0.12 h |

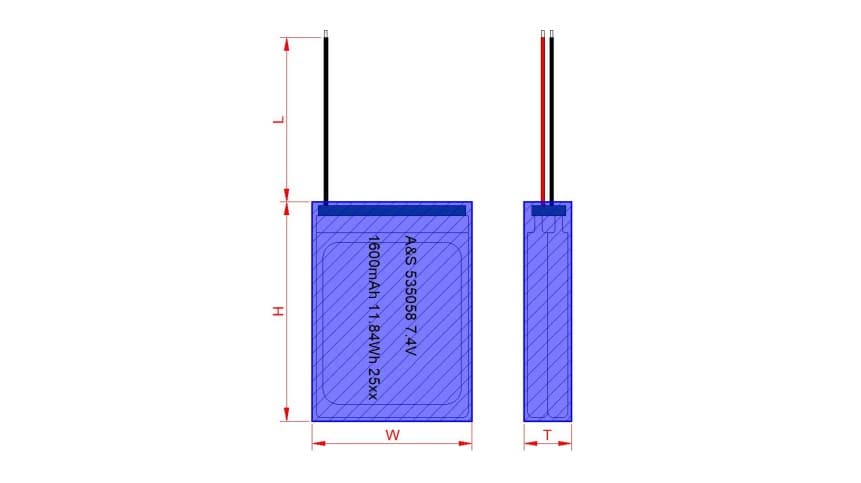

| 1600 mAh | 11.84 Wh | 2.37 h | 0.59 h | 0.24 h |

| 3000 mAh | 22.20 Wh | 4.44 h | 1.11 h | 0.44 h |

| 6200 mAh | 45.88 Wh | 9.18 h | 2.29 h | 0.92 h |

*(Calculations shown use Wh = (mAh/1000)7.4 and RunTime = Wh ÷ W.)

Common applications and selection tips

I’ve specified 7.4V packs across a few verticals — here’s how I choose the pack for each:

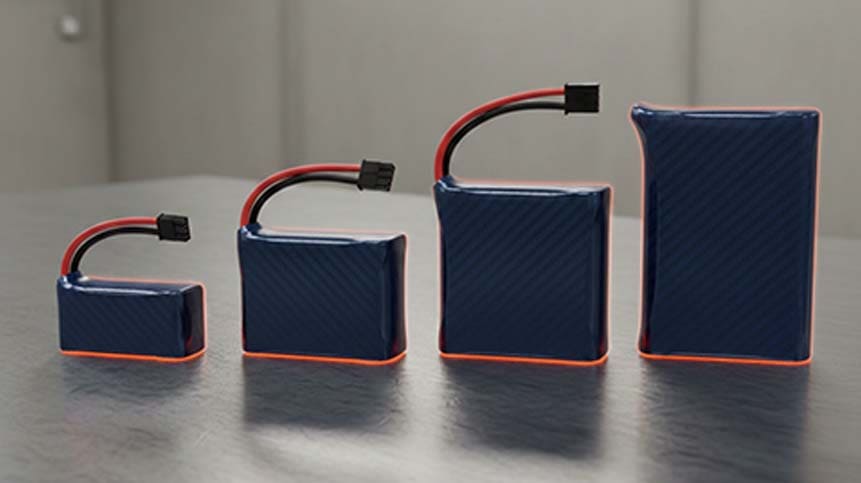

Drones & FPV (racing or micro)

-

Typical: high C-rating, lower mAh for weight savings (e.g., 700–2200 mAh at 30C+). If you need endurance choose higher mAh but expect weight penalty. Use precise C margin for peak thrust.

RC cars, boats, small robotics

-

Medium C and mid-range mAh (800–3000 mAh) are common; pick connector (EC2, XT30) for current. Balance between weight and run time is the key.

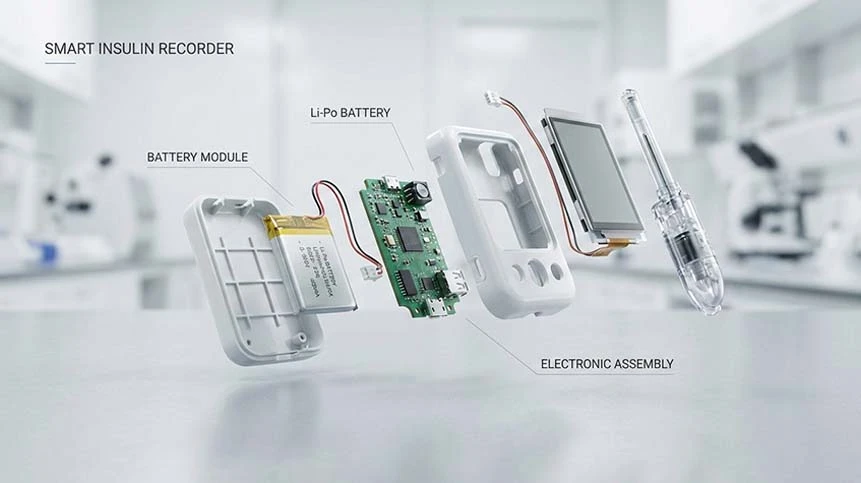

Portable equipment, camera rigs, radios

-

Higher mAh (3000–6200 mAh) and lower C ratings are typical — designed for longer run time at moderate current. Example 2S 6200 mAh battery specs are shown in manufacturer listings.

Longevity & cycle life (how to maximize pack life)

I follow these practical rules to extend cycle life and keep packs healthy:

-

Store at ~40-50% state of charge (SoC) for long term storage (around 3.8–3.9V per cell). This reduces aging.

-

Avoid full-charge storage where possible (4.2V/cell increases chemical stress).

-

Keep cells at moderate temperatures (not hot). High charge or discharge temperatures reduce cycle life.

Procurement & specifying custom packs (what I request in RFQ)

When I ask suppliers for quotes I include:

-

Nominal pack voltage and cell count (2S / 7.4V), required capacity (mAh), maximum continuous and peak discharge current (A), connector type, physical dimensions/weight, expected cycle life (e.g., >300 cycles @ 80% DOD), required certifications (UN 38.3, CE, RoHS), and whether BMS/protection circuit is needed. Provide a sample pack and datasheet request. Manufacturer product pages commonly list these values — use them to compare quotes.

References

-

Large-Battery / LiPo voltage guide — per-cell voltage & cutoffs

-

Example manufacturer spec (product page): RadioMaster 2S 7.4V 6200mAh

Frequently Asked Questions (FAQ)

Q: Is a 7.4V LiPo battery the same as a 2S LiPo?

A: Yes — “2S” means two cells in series; nominal per-cell voltage is ~3.7V so the pack nominal voltage is ~7.4V. Fully charged, the pack reads ~8.4V.

Q: How do I choose the right capacity and C-rating?

A: Start with your required continuous current (A). Multiply capacity (Ah) by C to get theoretical max continuous current. Add margin (20–50%) for safety. For endurance, increase mAh but check that weight fits your system.

Q: How long will a 7.4V 3000mAh pack power my 20W device?

A: Theoretical run time = Wh ÷ W = (3.0 Ah × 7.4 V) ÷ 20 W ≈ 1.11 hours. Expect real-world results slightly lower due to inefficiencies. See the run-time table above.

Q: What charger should I use?

A: Use a balance charger designed for LiPo (2S). Charge at or below the manufacturer’s recommended max charge current (commonly ≤1C for longevity; some cells allow higher). Always use the balance connector during charge.

Q: What certifications should I ask for?

A: At a minimum: UN 38.3 for transport, local CE/ROHS as applicable, and MSDS sheets. For medical devices or aviation use, ask for additional compliance documentation.

-

May.2026.02.127.4V LiPo Battery — A Practical Guide (2S Li-Po / 7.4V)Learn More

May.2026.02.127.4V LiPo Battery — A Practical Guide (2S Li-Po / 7.4V)Learn More -

May.2026.02.10Lithium Polymer Battery Supply Chain Explained: From Raw Materials to Custom Power SolutionsLearn More

May.2026.02.10Lithium Polymer Battery Supply Chain Explained: From Raw Materials to Custom Power SolutionsLearn More -

May.2026.02.097.2V Li-ion Battery Pack – A Complete Technical & Application GuideLearn More

May.2026.02.097.2V Li-ion Battery Pack – A Complete Technical & Application GuideLearn More -

May.2026.02.06Lithium-Ion Battery Energy Density: How Much Energy Can We Really Store?Learn More

May.2026.02.06Lithium-Ion Battery Energy Density: How Much Energy Can We Really Store?Learn More -

May.2026.02.05Smart Insulin Recorder Battery: Powering Accurate Diabetes Management DevicesLearn More

May.2026.02.05Smart Insulin Recorder Battery: Powering Accurate Diabetes Management DevicesLearn More