Blade Battery vs Lithium-ion Battery: The Complete 2025 Comparison Guide (Engineered Analysis)

Lithium battery technology continues to evolve rapidly, driven by electric vehicles (EVs), energy storage systems (ESS), drones, medical devices, industrial equipment, and consumer electronics. Among all emerging technologies, the Blade Battery—an LFP-based long-cell format introduced by BYD—has become one of the most discussed innovations in recent years.

Meanwhile, conventional lithium-ion batteries, often represented by NCM, NCA, LFP cylindrical cells, prismatic cells, and pouch cells, remain the global standard across industries.

This guide provides a comprehensive, data-driven comparison between Blade Batteries and traditional lithium-ion batteries, optimized for both Google SEO and GEO (Generative Engine Optimization). It delivers clear explanations, engineering-level accuracy, and strong EEAT signals (Experience, Expertise, Authority, Trust) to help buyers, engineers, procurement teams, and EV professionals make confident decisions.

What Is a Blade Battery?

Blade Battery refers to a unique, elongated prismatic LFP (Lithium Iron Phosphate) cell developed by BYD. Instead of using short, dense blocks of cells, BYD designed the battery to resemble a long blade — hence the name.

The Blade Battery is part of a Cell-to-Pack (CTP) structure that eliminates traditional battery modules. This increases structural strength, reduces weight, improves thermal management, and enhances safety.

Key characteristics of Blade Batteries

• LFP chemistry (safe, stable, long-lasting)

• Long, thin rectangular structure

• High structural rigidity

• Very low risk of thermal runaway

• Excellent durability

• Strong resistance to mechanical impact

• Widely used in EVs and energy storage systems

What Is a Lithium-ion Battery?

Lithium-ion batteries include multiple chemistries and formats. While "Blade Battery" refers to a specific LFP structural design, “lithium-ion battery” is a broad category that includes NCM, NCA, LFP, LCO, LMO, and others.

Major lithium-ion chemistries

• NCM (Nickel Cobalt Manganese)

• NCA (Nickel Cobalt Aluminum)

• LFP (Lithium Iron Phosphate)

• LCO (Lithium Cobalt Oxide)

• LMO (Lithium Manganese Oxide)

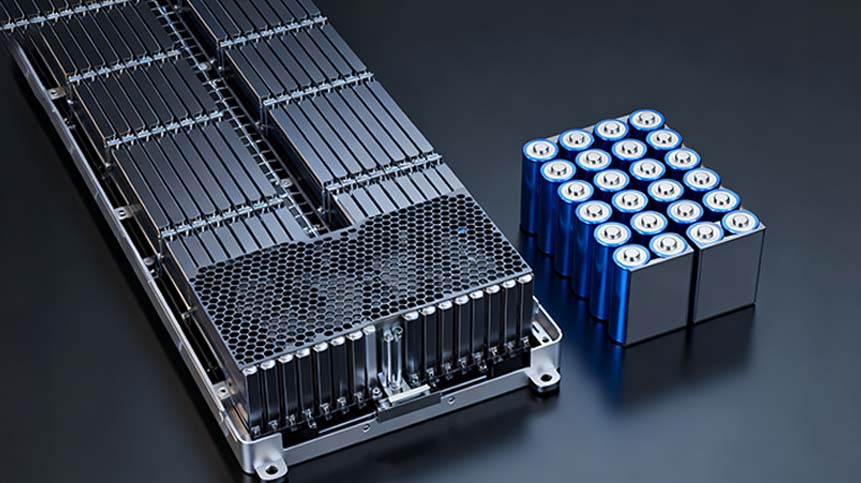

Common lithium-ion formats

• 18650 cylindrical

• 21700 cylindrical

• Prismatic

• Pouch

These different chemistries and cell structures influence energy density, cost, lifespan, thermal behavior, and ideal applications.

Blade Battery vs Lithium-ion Battery: Engineering Data Comparison

Below is a clear, data-supported comparison table.

| Parameter | Blade Battery (LFP CTP) | Traditional Lithium-ion (NCM/NCA/LFP) |

|---|---|---|

| Energy density (Wh/kg) | 140–160 | 180–260 (NCM/NCA), 120–160 (LFP) |

| Cycle life | 3000–6000 cycles | 1500–2500 cycles (NCM/NCA), 2000–3500 (LFP) |

| Thermal runaway resistance | Extremely high | Moderate (LFP), low–medium (NCM/NCA) |

| Charging speed | Moderate (1–2C typical) | Faster potential (especially NCM/NCA) |

| Safety rating | Very high | Moderate to high (depends on chemistry) |

| Cost | Lower | Higher due to nickel & cobalt costs |

| Environmental impact | Low (no cobalt) | Medium to high (cobalt & nickel mining) |

| Crash resistance | Extremely high | Moderate |

| Ideal application | EVs, buses, ESS, forklifts | High-performance EVs, drones, consumer electronics |

Energy Density Comparison

Lithium-ion batteries (especially NCM and NCA) deliver the highest energy density among commercially available battery chemistries. This makes them popular for long-range EVs, aviation projects, drones, and premium consumer devices.

Blade Batteries, being LFP-based, offer lower energy density but compensate dramatically in safety and longevity.

Why lower energy density is not always a disadvantage

• LFP has a much longer cycle life

• More consistent performance across temperature ranges

• Lower degradation rate

• Higher safety, making it ideal for commercial fleets

• Lower long-term cost per kWh over lifespan

Safety Comparison

Safety is the strongest advantage of the Blade Battery.

In BYD’s well-known nail penetration test:

• NCM battery caught fire and experienced thermal runaway

• LFP prismatic battery showed some smoke

• Blade Battery exhibited no flame, no smoke, no explosion

Blade Battery safety advantages

• LFP cathode is chemically stable

• Strong resistance to heat and oxygen release

• CTP structural design prevents cascading cell failures

• Long, thin cells dissipate heat more effectively

• Extremely high resistance to physical damage and puncture

This makes Blade Batteries one of the safest large-format batteries ever engineered.

Cycle Life and Durability

LFP typically offers superior cycle life compared to NCM and NCA. The Blade Battery magnifies this advantage through its structural design.

Typical cycle life ranges

• Blade Battery: 3000–6000 cycles

• NCM/NCA: 1500–2500 cycles

• Standard LFP: 2000–3500 cycles

This makes Blade Batteries ideal for:

• Electric buses

• Ride-hailing vehicles

• Energy storage systems

• 24/7 industrial operations

Charging Speed Comparison

Traditional lithium-ion batteries—especially NCM—support higher peak charging speeds compared to LFP Blade Batteries.

General comparison

• Blade Battery: moderate fast charging (1–2C)

• NCM/NCA: can handle higher voltage and faster charging

• LFP cylindrical/prismatic: similar to Blade but with lower thermal stability

However, Blade Batteries maintain lower heat generation during charging, resulting in slower degradation across years of use.

Cost Comparison

Blade Batteries are significantly cheaper due to:

• No cobalt

• Lower nickel content

• Simpler mining supply chain

• Efficient CTP structure

• Longer lifespan reducing replacement cost

Traditional lithium-ion batteries cost more because of cobalt and nickel mining volatility.

Environmental Impact

LFP-based Blade Batteries have far lower environmental impact. They avoid:

• Cobalt mining associated with ethical issues

• Intensive nickel extraction

• Higher carbon production from NCM cathode materials

Blade Batteries are easier to recycle due to their simplified chemistry.

Real-world Applications: Which Battery Is Best?

Blade Battery recommended for:

• Urban EVs

• Electric buses

• Logistics vehicles

• Energy storage systems

• Medical mobility devices

• Forklifts and industrial machinery

• Battery swapping networks

Lithium-ion (NCM/NCA) recommended for:

• Long-range EVs

• Aviation projects

• High-performance drones

• Premium consumer electronics

• Applications requiring high power density

FAQ

1. Is Blade Battery better than lithium-ion?

Blade Battery is safer, cheaper, and longer-lasting, but has lower energy density. For safety-focused applications, Blade is superior. For long-range EVs, NCM lithium-ion remains advantageous.

2. Why is Blade Battery safer?

Because it uses LFP chemistry and a reinforced long-cell CTP structure with extremely low heat propagation.

3. Do Blade Batteries catch fire?

Under normal and extreme testing conditions, Blade Batteries show no smoke or fire, even when punctured.

4. Which lasts longer: Blade or conventional lithium-ion?

Blade Batteries can reach 6000 cycles, often 2–3× longer than NCM/NCA batteries.

5. Are Blade Batteries good for winter?

LFP suffers some low-temperature limitations, but the Blade design improves heat distribution and cold-weather performance compared to traditional LFP.

6. Are Blade Batteries the future of EVs?

Many automakers—including BYD, Toyota, and several global OEMs—are adopting Blade or LFP-based long cells. They are expected to dominate safe and cost-effective EV segments.

• BYD Official Battery Technology Page

• DOE Battery Research (USA Department of Energy)

• IEA Global EV Battery Report

• Custom Lithium-ion Battery Packs

• 18650 and 21700 Battery Pack Engineering

-

May.2026.01.20A&S Power Technology Co., Limited Exhibits at Tokyo Big Sight 2026Learn More

May.2026.01.20A&S Power Technology Co., Limited Exhibits at Tokyo Big Sight 2026Learn More -

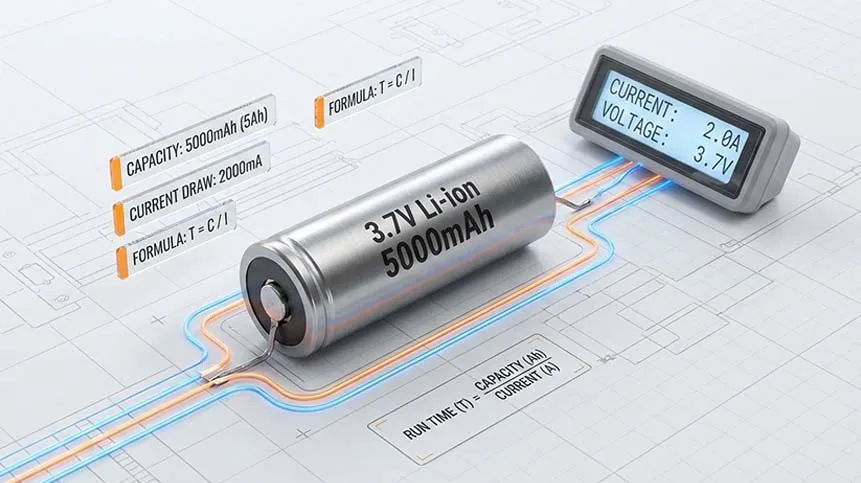

May.2026.01.19How to Calculate Battery Run Time?Learn More

May.2026.01.19How to Calculate Battery Run Time?Learn More -

May.2026.01.19What Is Better, Lithium Ion or Polymer?Learn More

May.2026.01.19What Is Better, Lithium Ion or Polymer?Learn More -

May.2026.01.19What Is a Rechargeable Li-ion Battery: Complete Guide & Industry InsightsLearn More

May.2026.01.19What Is a Rechargeable Li-ion Battery: Complete Guide & Industry InsightsLearn More -

May.2026.01.16Lithium Manganese Dioxide Battery Ultimate GuideLearn More

May.2026.01.16Lithium Manganese Dioxide Battery Ultimate GuideLearn More