An Environmentally-Friendly Battery Technology

An Environmentally-Friendly Battery Technology

The Emergence of Sustainable Energy Storage Solutions

The global energy storage industry is undergoing a profound transformation as environmentally-friendly battery technologies emerge to address the significant ecological challenges associated with conventional energy storage systems. Sustainable battery technologies represent a critical innovation in the pursuit of global decarbonization goals, offering reduced environmental impact throughout their lifecycle from material extraction and manufacturing to usage and ultimate disposal or recycling. The growing demand for these technologies reflects increasing environmental awareness among consumers, stricter regulatory frameworks governing electronic waste and carbon emissions, and industry recognition that sustainability represents both an ethical imperative and competitive advantage in rapidly evolving energy markets. Current market analysis indicates the global green technology sector, including environmentally-friendly batteries, reached approximately $850 billion in 2023 and continues to demonstrate robust growth as governments and corporations accelerate their sustainability initiatives and transition toward circular economy principles.

Environmentally-friendly battery technologies encompass diverse approaches including improved lithium-ion formulations with reduced environmental impact, alternative chemistry batteries utilizing abundant and non-toxic materials, and advanced recycling technologies that enable circular material flows. These innovations collectively address the environmental limitations of conventional batteries, which often involve energy-intensive manufacturing processes, utilize materials with problematic supply chains, and create challenging waste management issues at end-of-life. The development of truly sustainable battery systems requires holistic consideration of numerous environmental factors including greenhouse gas emissions during production, water usage, toxicity of materials, energy efficiency during use, and recyclability, rather than focusing exclusively on any single environmental metric. This comprehensive approach ensures that battery technologies contribute positively to broader sustainability objectives rather than simply shifting environmental impacts from one area to another.

Technological Innovations and Material Advancements

Lithium Iron Phosphate and Manganese-Based Batteries

Lithium iron phosphate (LFP) batteries have emerged as a leading environmentally-friendly battery technology, offering numerous advantages over conventional lithium-ion chemistries including reduced toxicity, improved safety characteristics, longer lifespan, and elimination of cobalt and nickel from their composition. The absence of cobalt addresses significant ethical concerns regarding mining practices in the Democratic Republic of Congo while eliminating supply chain vulnerabilities associated with this geographically concentrated material. LFP batteries demonstrate exceptional thermal stability and resistance to thermal runaway, reducing safety risks and potentially simplifying thermal management systems in applications ranging from electric vehicles to stationary energy storage. These safety advantages translate to reduced need for sophisticated battery management systems in some applications, potentially lowering overall system complexity and environmental impact.

Recent advancements in LFP technology have addressed historical limitations regarding energy density through improved electrode architectures, enhanced conductive additives, and optimized particle size distributions that improve lithium-ion diffusion kinetics. Contemporary LFP batteries achieve energy densities approaching 200 Wh/kg, sufficient for many applications while providing exceptional cycle life exceeding 4000 cycles in stationary storage applications. Manganese-rich cathode materials represent another promising development, utilizing abundant manganese rather than scarce cobalt or nickel while offering higher energy density than LFP chemistries. These manganese-based systems typically demonstrate voltages around 4.0V versus lithium, providing improved energy density compared to LFP's 3.2-3.3V operating voltage while maintaining similar advantages regarding material abundance, reduced toxicity, and improved thermal stability compared to conventional NMC batteries.

Aqueous and Solid-State Electrolyte Systems

Aqueous battery technologies represent another promising approach to environmentally-friendly energy storage, utilizing water-based electrolytes that eliminate flammability concerns associated with conventional organic electrolytes while reducing manufacturing complexity and environmental impact. Recent advancements in aqueous battery chemistry have addressed historical limitations including narrow electrochemical stability windows and lower energy density through innovative electrode materials and electrolyte formulations that enable higher operating voltages and improved performance. These systems typically utilize abundant elements including zinc, manganese, or iron rather than lithium, further enhancing their sustainability profile while potentially reducing costs and supply chain vulnerabilities associated with lithium extraction and processing.

Solid-state battery technology offers another pathway toward more environmentally-friendly energy storage through the elimination of flammable liquid electrolytes that represent safety hazards and complicate recycling processes. Solid electrolytes potentially enable the use of lithium metal anodes, dramatically increasing energy density while utilizing less material overall for equivalent energy storage capacity. Several solid electrolyte chemistries show particular promise for environmentally-friendly applications including oxide-based ceramics that offer excellent stability, sulfide-based glasses with high ionic conductivity, and polymer electrolytes that provide mechanical flexibility and manufacturing advantages. These solid-state systems typically exhibit superior thermal stability, reduced self-discharge, and longer cycle life than conventional lithium-ion batteries, though manufacturing challenges and cost considerations remain significant barriers to widespread commercialization.

Table: Environmental Impact Comparison of Battery Technologies

| Parameter | Conventional NMC | LFP Batteries | Aqueous Zinc | Solid-State |

|---|---|---|---|---|

| Cobalt Content | 10-20% of cathode | 0% | 0% | 0-10% |

| Thermal Runaway Risk | High | Moderate | Very Low | Low |

| Recyclability | Complex, energy-intensive | Simpler process | Highly recyclable | Promising but unproven |

| Manufacturing Emissions | 60-100 kg CO2/kWh | 40-70 kg CO2/kWh | 20-40 kg CO2/kWh | Unknown (early stage) |

| Material Abundance | Limited cobalt/nickel | Abundant iron/phosphorus | Abundant zinc | Varies by chemistry |

| Toxicity | Moderate (cobalt/nickel) | Low | Very Low | Low-Moderate |

Manufacturing Processes and Supply Chain Considerations

Sustainable Material Sourcing and Processing

The environmental footprint of battery technologies extends beyond operational characteristics to encompass material sourcing, manufacturing processes, and supply chain considerations that collectively determine overall sustainability. Environmentally-friendly battery manufacturers increasingly prioritize responsible sourcing of raw materials through certified supply chains that verify ethical mining practices, minimal environmental disruption, and fair labor conditions. Lithium extraction methods are evolving toward less water-intensive processes including direct lithium extraction (DLE) from brines that significantly reduce water consumption and land disruption compared to conventional evaporation ponds. These advanced extraction technologies typically recover 70-90% of lithium from brines compared to 30-50% for conventional methods, reducing resource waste while minimizing environmental impact.

The processing of battery materials represents another significant opportunity for environmental improvement through increased energy efficiency, reduced chemical usage, and enhanced recovery of process materials. Innovative cathode manufacturing approaches including hydro-to-cathode processes that eliminate intermediate steps and dry electrode manufacturing that removes energy-intensive solvent drying operations can reduce energy consumption during electrode production by 30-50% while eliminating volatile organic compound emissions. These process innovations not only reduce environmental impact but potentially lower manufacturing costs, creating economic incentives alongside environmental benefits. The geographical distribution of manufacturing facilities also influences environmental impact through transportation requirements and regional energy mixes, with leading manufacturers increasingly locating production in regions with renewable energy sources to minimize carbon footprint.

Circular Economy and Closed-Loop Manufacturing

The transition toward circular economy principles represents a fundamental aspect of environmentally-friendly battery technology, aiming to minimize waste and maximize material utilization throughout the product lifecycle. Closed-loop manufacturing systems recover materials from production scrap and end-of-life batteries for direct reuse in new products, reducing virgin material requirements and associated environmental impacts. Advanced recycling technologies including direct cathode regeneration approaches that restore spent cathode materials to like-new condition rather than breaking them down to elemental components offer particularly promising environmental benefits through reduced energy consumption and higher value material recovery.

Battery manufacturers increasingly design products specifically for disassembly and recycling, incorporating features including standardized connectors, easily separable components, and material identification systems that facilitate automated sorting and processing. These design-for-recycling principles significantly improve the economics and environmental performance of recycling operations, which have historically struggled with the diverse and complex nature of battery products. The development of comprehensive battery passport systems that digitally record material composition, manufacturing history, and performance data further supports circular economy implementation by providing recyclers with detailed information to optimize recovery processes. These circular approaches transform batteries from linear products with beginning and end points to continuous material carriers that maintain value through multiple lifecycles.

Performance Characteristics and Application Suitability

Technical Performance and Operational Parameters

Environmentally-friendly battery technologies demonstrate performance characteristics that increasingly compete with conventional options while offering superior environmental profiles. LFP batteries provide exceptional cycle life typically exceeding 3000-5000 cycles in stationary storage applications, significantly outperforming conventional NMC batteries that typically achieve 1500-2500 cycles under similar conditions. This extended lifespan directly reduces environmental impact by distributing manufacturing impacts across more energy storage service over time. The superior safety characteristics of many environmentally-friendly technologies including LFP and aqueous batteries potentially reduce requirements for sophisticated safety systems and thermal management, further improving overall system efficiency and environmental performance.

Energy efficiency represents another critical performance parameter where environmentally-friendly technologies often excel, particularly aqueous systems that typically demonstrate round-trip efficiencies exceeding 85-90% compared to 90-95% for conventional lithium-ion batteries. While slightly lower in absolute terms, this efficiency remains highly competitive particularly when considering the significantly reduced environmental impact throughout the manufacturing phase. The operating temperature range of environmentally-friendly batteries continues to improve through material innovations and system design enhancements, with many newer formulations performing effectively across wider temperature ranges than previous generations. These performance improvements increasingly enable environmentally-friendly batteries to compete across diverse applications including electric vehicles, renewable energy storage, and portable electronics where performance requirements have historically favored conventional chemistries despite environmental drawbacks.

Application-Specific Implementation

Different environmentally-friendly battery technologies demonstrate particular advantages in specific applications based on their unique performance characteristics and environmental profiles. Stationary energy storage applications particularly benefit from LFP batteries due to their exceptional cycle life, safety characteristics, and reduced environmental impact, with major energy storage projects increasingly utilizing LFP chemistry rather than conventional NMC. The residential energy storage market has particularly embraced LFP technology, where safety considerations outweigh energy density concerns and long lifespan provides economic advantages through reduced replacement frequency.

Electric vehicles represent a more challenging application for environmentally-friendly batteries due to stringent energy density requirements, though LFP adoption continues to increase particularly in standard-range vehicles where cost and safety advantages outweigh range limitations. Emerging solid-state and advanced lithium metal technologies promise to bridge this energy density gap while maintaining environmental advantages, though commercial deployment remains limited. Consumer electronics applications increasingly utilize environmentally-friendly batteries where possible, particularly in products emphasizing sustainability as a key differentiator. The specific performance requirements of each application including energy density, power density, cycle life, and safety characteristics influence the optimal choice of environmentally-friendly battery technology, with different chemistries offering advantages in different contexts.

Environmental Impact Assessment and Lifecycle Analysis

Comprehensive Carbon Footprint Evaluation

The environmental performance of battery technologies must be evaluated through comprehensive lifecycle assessment (LCA) that considers all phases from material extraction through manufacturing, use, and end-of-life management. Conventional lithium-ion batteries typically generate 60-100 kg CO2 equivalent per kWh of capacity during manufacturing, with variations based on energy source, manufacturing efficiency, and material transportation requirements. Environmentally-friendly technologies can reduce this manufacturing carbon footprint by 30-50% through material selection, process improvements, and renewable energy integration during production. The extended lifespan of many environmentally-friendly batteries further reduces their carbon footprint per kWh delivered over the product lifecycle, often achieving 40-60% lower emissions than conventional alternatives when considering complete lifecycle impacts.

The use phase significantly influences overall environmental impact through efficiency losses during charging and discharging, with round-trip efficiency differences of just 2-3% potentially outweighing manufacturing impacts over the battery's operational life. Most environmentally-friendly technologies demonstrate efficiency characteristics comparable to conventional options, minimizing additional use-phase impacts. The geographical context of battery deployment also influences environmental performance through regional electricity generation mixes that determine carbon intensity during charging, with identical batteries exhibiting significantly different lifecycle emissions depending on whether they are charged using renewable energy or fossil fuel-based electricity. These complex interactions necessitate holistic environmental assessment rather than focusing exclusively on manufacturing impacts or any single environmental metric.

Resource Utilization and Ecosystem Impacts

Beyond carbon emissions, environmentally-friendly battery technologies aim to reduce impacts on water resources, ecosystem integrity, and human health through careful material selection and process design. Conventional battery production typically consumes 30-70 liters of water per kWh of capacity, primarily for material processing and cooling requirements, while environmentally-friendly approaches utilizing dry electrode manufacturing and closed-loop water systems can reduce this consumption by 50-80%. The toxicity of battery materials represents another critical consideration, with conventional cobalt-containing batteries posing particular concerns regarding mining impacts, manufacturing exposure, and potential leaching from improperly disposed products.

The land use implications of battery production extend beyond immediate manufacturing facilities to encompass mining operations, material transportation infrastructure, and waste management requirements. Environmentally-friendly technologies utilizing abundant materials typically reduce land disruption by minimizing requirements for intensive mining operations associated with scarce materials like cobalt. The integration of renewable energy directly into manufacturing facilities further reduces land impact by avoiding the separate land requirements for off-site renewable generation, though manufacturing colocation involves complex logistical considerations. These multifaceted environmental impacts require comprehensive assessment methodologies that consider all aspects of resource utilization and ecosystem interaction rather than focusing exclusively on carbon emissions or energy consumption.

Market Adoption and Implementation Challenges

Economic Considerations and Cost Competitiveness

The adoption of environmentally-friendly battery technologies faces significant economic challenges despite their environmental advantages, particularly regarding initial cost premiums compared to conventional alternatives. LFP batteries have achieved approximate cost parity with conventional lithium-ion batteries in many applications, though other environmentally-friendly technologies including solid-state and aqueous systems typically command significant premiums due to lower manufacturing volumes and less mature production processes. These cost differences reflect the complex interplay between material expenses, manufacturing scale, production yields, and research and development amortization that collectively determine final product pricing.

The total cost of ownership for environmentally-friendly batteries often proves competitive despite higher initial costs due to longer lifespan, reduced maintenance requirements, and lower safety system costs. However, market adoption frequently prioritizes initial cost over lifecycle economics, particularly in consumer markets and price-sensitive applications. Government policies including carbon pricing, extended producer responsibility requirements, and sustainability incentives help bridge this economic gap by internalizing environmental externalities that conventional pricing models typically ignore. Continuing manufacturing scale increases and process improvements steadily reduce costs for environmentally-friendly technologies, with many projections indicating cost parity across most applications within 3-5 years as production volumes increase and manufacturing efficiencies improve.

Infrastructure and Integration Challenges

The implementation of environmentally-friendly battery technologies faces numerous infrastructure challenges including manufacturing equipment compatibility, recycling facility adaptation, and charging system requirements. Existing battery manufacturing infrastructure primarily supports conventional lithium-ion production, requiring significant modification or replacement to accommodate alternative chemistries with different material handling, electrode processing, and cell assembly requirements. These infrastructure investments create adoption barriers despite environmental advantages, particularly for established manufacturers with substantial existing manufacturing assets. The development of flexible manufacturing platforms that can accommodate multiple battery chemistries represents a promising approach to reducing these transition barriers.

Recycling infrastructure requires similar adaptation to handle new battery chemistries, with existing recycling processes optimized for conventional lithium-ion systems that may prove inefficient or ineffective for alternative technologies. The standardization of battery designs, material labeling, and disassembly features would significantly improve recycling effectiveness but requires industry coordination that has proven challenging historically. Charging infrastructure must also adapt to the different voltage characteristics, thermal management requirements, and safety considerations of environmentally-friendly batteries, though these adaptations typically involve relatively modest changes compared to manufacturing and recycling transformations. These infrastructure challenges necessitate coordinated development across multiple sectors to ensure that environmentally-friendly battery technologies can achieve their full potential environmental benefits.

Future Development Directions and Industry Trends

Next-Generation Materials and Chemistry Innovations

The future development of environmentally-friendly battery technologies will likely focus on advanced materials that further reduce environmental impact while maintaining or improving performance characteristics. Lithium-sulfur batteries represent a promising direction utilizing abundant sulfur rather than scarce metals, offering theoretical energy densities 3-5 times higher than conventional lithium-ion batteries while utilizing low-cost, non-toxic materials. Current research addresses historical limitations regarding cycle life and efficiency through advanced cathode architectures, protective interlayers, and electrolyte formulations that stabilize the lithium-metal anode and prevent polysulfide shuttle. These innovations potentially enable batteries with significantly reduced environmental impact and superior performance, though commercial viability remains several years away.

Sodium-ion battery technology offers another promising pathway toward environmentally-friendly energy storage, utilizing abundant sodium rather than lithium while offering similar performance characteristics in many applications. Sodium-ion batteries typically operate at slightly lower voltages than lithium-ion systems but utilize aluminum rather than copper for current collectors, reducing cost and simplifying recycling. Recent advancements have improved energy density to approximately 160-180 Wh/kg, sufficient for many stationary storage and lighter electric vehicle applications. The environmental advantages of sodium-ion batteries include reduced mining impacts, elimination of lithium extraction requirements, and compatibility with simpler recycling processes, though their overall environmental performance depends heavily on specific electrode materials and manufacturing processes.

System-Level Integration and Sustainability Enhancement

Beyond individual battery improvements, system-level integration approaches offer significant opportunities for enhancing the environmental performance of energy storage systems. The development of adaptive battery management systems that optimize charging patterns based on renewable energy availability can significantly reduce the carbon intensity of electricity used for charging, particularly when integrated with smart grid systems and real-time carbon intensity tracking. These intelligent systems can also extend battery lifespan through optimized operating strategies that minimize degradation, reducing replacement frequency and associated environmental impacts.

The integration of energy storage with renewable generation in hybrid systems offers another pathway toward improved environmental performance through reduced transmission losses, optimized renewable utilization, and decreased requirements for backup fossil fuel generation. These integrated systems typically demonstrate superior environmental performance compared to separate components through synergistic operation that maximizes renewable energy utilization and minimizes overall material requirements. The continuing digitalization of energy systems enables more sophisticated optimization approaches that further enhance environmental performance while maintaining reliability and cost effectiveness. These system-level considerations will become increasingly important as energy storage deployment expands, with environmental performance determined by complete system operation rather than individual component characteristics.

-

May.2026.02.127.4V LiPo Battery — A Practical Guide (2S Li-Po / 7.4V)Learn More

May.2026.02.127.4V LiPo Battery — A Practical Guide (2S Li-Po / 7.4V)Learn More -

May.2026.02.10Lithium Polymer Battery Supply Chain Explained: From Raw Materials to Custom Power SolutionsLearn More

May.2026.02.10Lithium Polymer Battery Supply Chain Explained: From Raw Materials to Custom Power SolutionsLearn More -

May.2026.02.097.2V Li-ion Battery Pack – A Complete Technical & Application GuideLearn More

May.2026.02.097.2V Li-ion Battery Pack – A Complete Technical & Application GuideLearn More -

May.2026.02.06Lithium-Ion Battery Energy Density: How Much Energy Can We Really Store?Learn More

May.2026.02.06Lithium-Ion Battery Energy Density: How Much Energy Can We Really Store?Learn More -

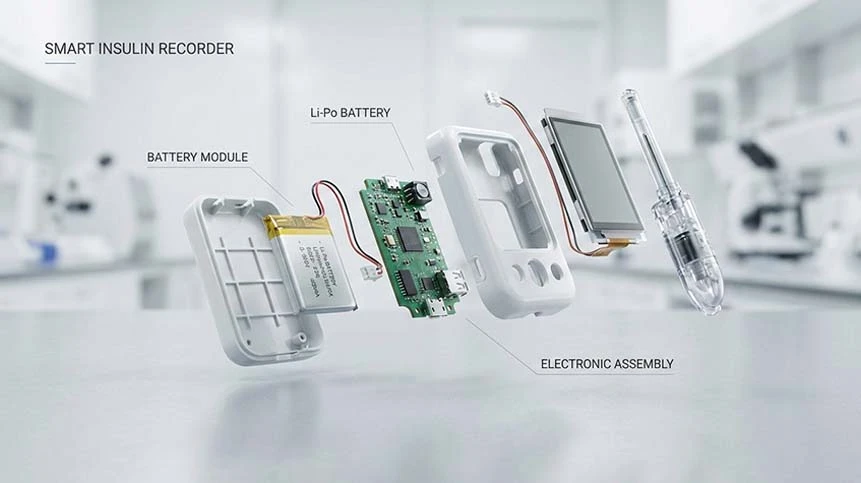

May.2026.02.05Smart Insulin Recorder Battery: Powering Accurate Diabetes Management DevicesLearn More

May.2026.02.05Smart Insulin Recorder Battery: Powering Accurate Diabetes Management DevicesLearn More