How to Calculate Battery Run Time?

Battery run time is one of the most important considerations in battery-powered product design. Whether you are developing a medical device, IoT sensor, wearable product, or portable electronic system, knowing how long a battery will last under real operating conditions is critical.

This guide explains how to calculate battery run time using standard formulas, practical examples, and real-world factors that significantly affect actual battery performance.

- What Is Battery Run Time?

- Basic Battery Run Time Formula

- Understanding Battery Capacity

- Load Current Explained

- Battery Run Time Calculation Examples

- Why Calculated Run Time Is Often Inaccurate

- Lithium-Ion vs Lithium Polymer Battery Run Time

- Estimating Real-World Battery Run Time

- Choosing the Right Battery

- Frequently Asked Questions

What Is Battery Run Time?

Battery run time refers to the length of time a battery can continuously supply power to a device before its voltage drops below the usable operating range.

In simple terms, battery run time answers the question: “How long will my device operate on this battery?”

Battery run time depends on more than just battery capacity. Load current, discharge rate, efficiency losses, temperature, and battery aging all play a role.

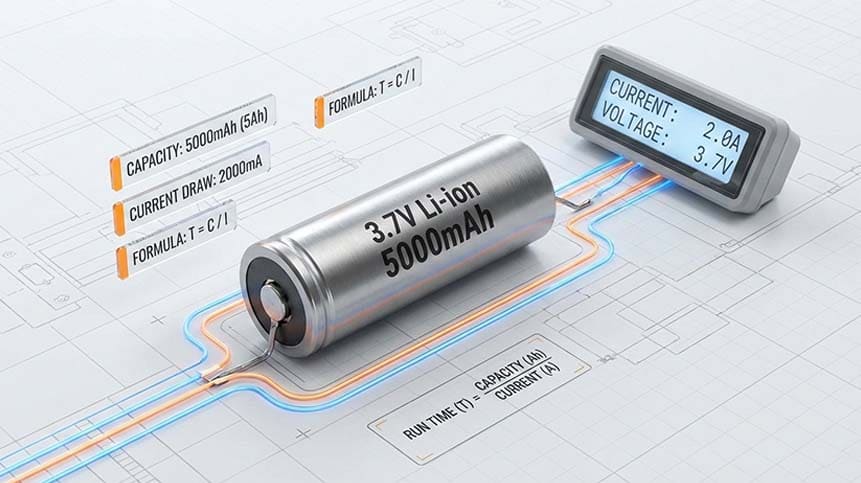

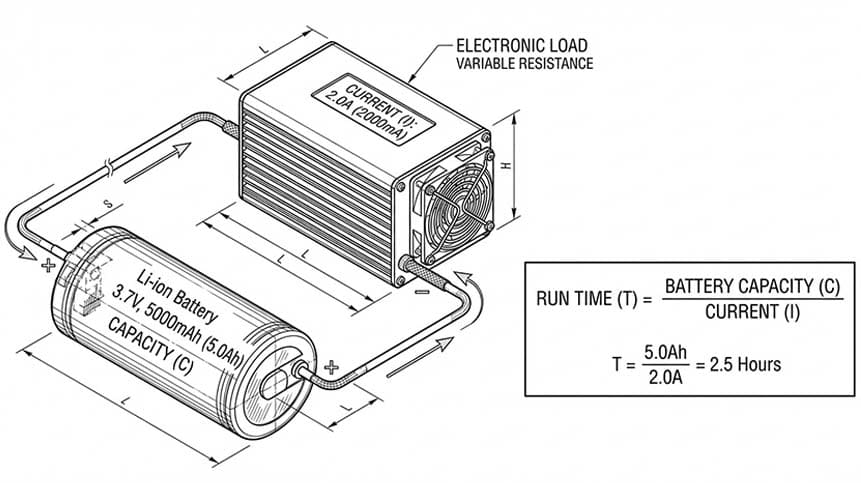

Basic Battery Run Time Formula

The most commonly used calculation formula is:

-

Battery capacity is measured in ampere-hours (Ah) or milliampere-hours (mAh)

-

Load current is the average current drawn by the device

A 2000mAh (2Ah) battery powering a device that draws 500mA (0.5A):

2Ah ÷ 0.5A = 4 hours (theoretical)

This formula provides a theoretical value. Real-world results are usually lower.

Understanding Battery Capacity (Ah vs mAh)

Battery capacity indicates how much electrical charge a battery can store.

-

1 Ah = 1000 mAh

-

A 3000mAh battery can theoretically supply:

-

3000mA for 1 hour

-

1500mA for 2 hours

-

300mA for 10 hours

-

However, battery capacity ratings are typically measured under controlled laboratory conditions and may not reflect actual operating environments.

Load Current: The Most Critical Variable

Load current is the amount of current your device consumes during operation.

- Many devices draw variable current

- Peak current and average current are different

- Motors, displays, and wireless modules cause current spikes

For accurate battery run time calculation, always use average operating current.

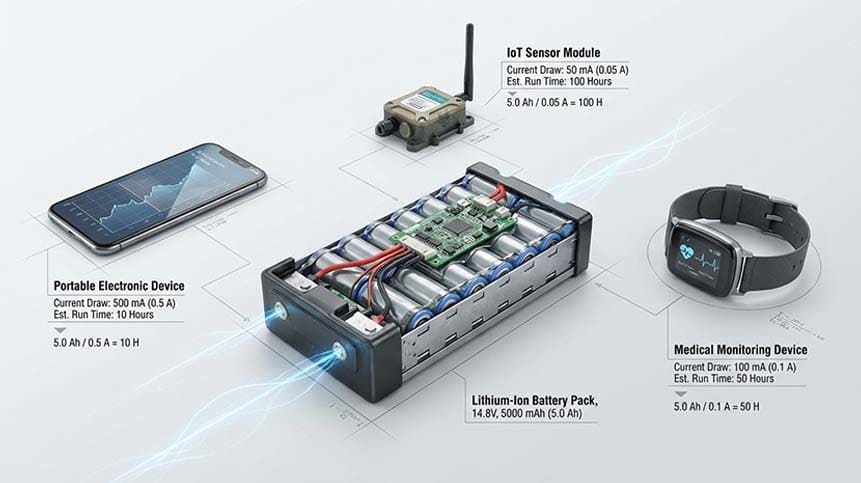

Battery Run Time Calculation Examples

Example 1: Small Electronics Device

Battery: 3.7V 2000mAh lithium-ion battery

Average current: 400mA

2Ah ÷ 0.4A = 5 hours (theoretical)

After efficiency loss (~80%): ≈4 hours

Example 2: IoT Device

Battery: 3.7V 5000mAh Li-ion battery

Average current: 100mA

5Ah ÷ 0.1A = 50 hours

Example 3: Medical Device Application

Battery: Custom 3000mAh LiPo battery

Average current: 600mA

3Ah ÷ 0.6A = 5 hours

Practical design assumption: 4–4.5 hours

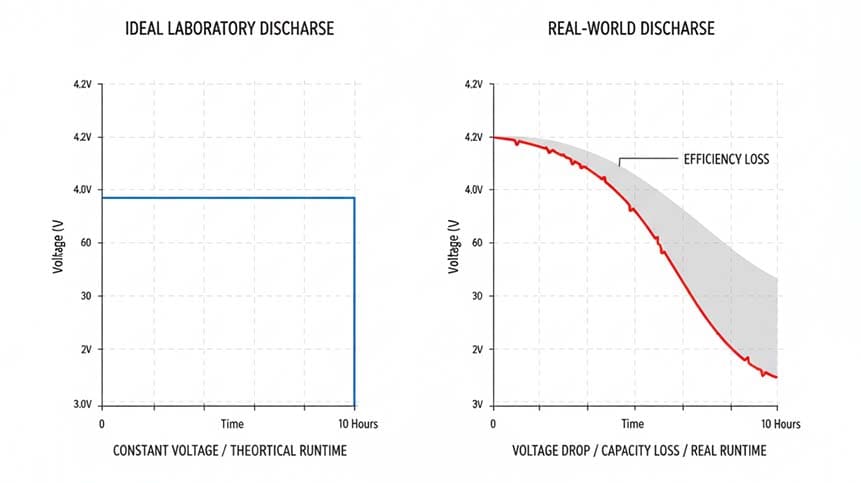

Why Calculated Battery Run Time Is Often Inaccurate

The basic formula does not consider several important real-world factors.

1. Discharge Efficiency

Battery capacity is not fully usable due to internal resistance and voltage drop.

Typical efficiency:

-

Lithium-ion: 80–90%

-

Lithium polymer: 75–90%

2. Battery Discharge Rate (C-Rate)

Higher discharge rates reduce effective capacity.

Example:

-

A battery rated at 2000mAh at 0.2C

-

May deliver only 1600–1800mAh at 1C

3. Voltage Cutoff Limits

Many devices stop operating before the battery is fully discharged to protect electronics or the battery itself.

4. Temperature Effects

-

Low temperatures reduce available capacity

-

High temperatures accelerate degradation

5. Battery Aging

As batteries age:

-

Internal resistance increases

-

Available capacity decreases

A battery may lose 20–30% capacity after hundreds of charge cycles.

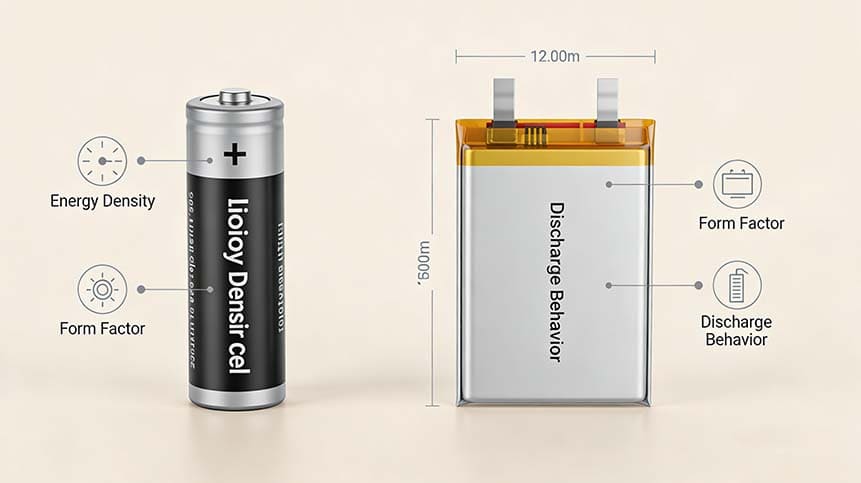

Lithium-Ion vs Lithium Polymer Battery Run Time

Both lithium-ion and lithium polymer batteries follow the same calculation principles, but performance characteristics differ.

| Factor | Li-ion | LiPo |

|---|---|---|

| Energy Density | High | High |

| Form Factor | Fixed | Flexible |

| Typical Use | Consumer electronics | Medical & wearable devices |

Run time differences mainly depend on cell quality and discharge conditions, not chemistry alone.

Estimating Real-World Battery Run Time

To get closer to real performance:

-

Measure average operating current

-

Apply efficiency factor (0.75–0.85)

-

Consider peak current and voltage drop

-

Account for temperature and aging

Choosing the Right Battery Based on Run Time

When selecting a battery, engineers should consider:

-

Required operating time

-

Peak and average current

-

Physical size constraints

-

Safety standards

-

Charging method

For applications such as medical devices, IoT equipment, and wearable electronics, battery run time should be calculated during the design stage, not after product development.

Frequently Asked Questions

How long will a 3000mAh battery last?

At 500mA load, theoretical run time is 6 hours. Practical run time is usually 4.5–5 hours.

Does higher voltage increase run time?

No. Run time depends on capacity and current, not voltage alone.

Why does my battery drain faster than calculated?

High discharge rate, efficiency loss, temperature, and battery aging are common causes.

Frequently Asked Questions

Battery run time calculation is a fundamental step in battery-powered product design. While simple formulas provide a starting point, real-world performance depends on many interacting factors.

For critical applications, accurate load measurement and proper safety margins are essential to ensure reliable operation.

-

May.2026.01.23Lithium LiPo Battery for Internet of Things (IoT) and Smart HardwareLearn More

May.2026.01.23Lithium LiPo Battery for Internet of Things (IoT) and Smart HardwareLearn More -

May.2026.01.22Lithium LiPo Battery for Medical and Health Monitoring EquipmentLearn More

May.2026.01.22Lithium LiPo Battery for Medical and Health Monitoring EquipmentLearn More -

May.2026.01.22Lithium LiPo Battery for Beauty Products (K-Beauty & Beyond)Learn More

May.2026.01.22Lithium LiPo Battery for Beauty Products (K-Beauty & Beyond)Learn More -

May.2026.01.22Lithium LiPo Battery for Portable Consumer Electronic DevicesLearn More

May.2026.01.22Lithium LiPo Battery for Portable Consumer Electronic DevicesLearn More -

May.2026.01.2114500 Battery vs AA Battery: A Complete Technical and Application GuideLearn More

May.2026.01.2114500 Battery vs AA Battery: A Complete Technical and Application GuideLearn More