Problem that lithium battery pack need to improved

Problems That Lithium Battery Packs Need to Improve

Critical Challenges in Modern Lithium Battery Technology

Lithium battery packs represent the cornerstone of modern energy storage systems, yet they face numerous significant challenges that require urgent attention and technological advancement. Despite substantial progress over the past decade, current lithium battery technologies continue to struggle with fundamental limitations including energy density constraints, safety concerns, cost pressures, and environmental impacts that hinder their optimal performance across various applications. The global lithium-ion battery market, valued at approximately $120 billion in 2024, continues to experience rapid growth projected at 18-22% annually, but this expansion brings increasing scrutiny to the technological shortcomings that remain unresolved. These challenges become particularly critical as batteries scale from consumer electronics to electric vehicles and grid storage applications, where performance deficiencies translate to substantial practical limitations and potential safety hazards that affect adoption rates and user confidence in energy storage solutions.

Industry analysts and research institutions have identified multiple areas requiring improvement, with particular emphasis on energy density limitations that restrict device runtime, safety issues that occasionally lead to highly publicized incidents, and cost factors that continue to impede broader adoption despite significant price reductions. The inherent electrochemical characteristics of lithium-based systems create fundamental trade-offs between energy density, power density, cycle life, and safety that engineers must balance through sophisticated design and management systems. These compromises often result in suboptimal performance in real-world conditions compared to theoretical possibilities, highlighting the need for continued research and development across multiple fronts including materials science, manufacturing processes, and system integration approaches. Addressing these challenges requires coordinated efforts from researchers, manufacturers, and policymakers to advance battery technology while ensuring safety, affordability, and sustainability across the product lifecycle.

Energy Density and Performance Limitations

Specific Energy and Volumetric Constraints

The energy density of lithium battery packs remains a fundamental limitation despite continuous incremental improvements, restricting application potential across multiple sectors including electric vehicles, portable electronics, and aerospace systems. Current commercial lithium-ion batteries typically achieve energy densities between 250-300 Wh/kg at the cell level and 150-200 Wh/kg at the pack level when accounting for packaging, management systems, and safety structures. This energy density limitation directly translates to practical constraints including limited electric vehicle range, frequent recharging requirements for portable devices, and payload restrictions for aerial applications where weight significantly impacts performance. The gap between theoretical energy densities of battery materials and practically achieved values remains substantial, indicating significant room for improvement through advanced materials and engineering approaches.

The volumetric energy density similarly constrains device design and functionality, particularly for compact consumer electronics where space premiums drive manufacturers to minimize battery volume while maintaining acceptable runtime. This limitation forces compromises in device thickness, component arrangement, and feature sets that could otherwise enhance user experience and functionality. Even relatively modest improvements in volumetric energy density could enable revolutionary product designs and capabilities across multiple application domains, highlighting the importance of continued research into higher-density electrode materials, more efficient packaging approaches, and reduced ancillary component sizes. The industry's transition to higher-nickel cathode materials and silicon-containing anodes represents steps toward addressing these limitations, though these advancements introduce their own challenges including cost increases and potential safety implications.

Power Density and Rate Capability Challenges

High-power applications including power tools, electric vehicles, and grid frequency regulation require battery packs capable of delivering substantial current without excessive voltage drop or overheating. Current lithium battery technologies face inherent trade-offs between energy density and power density, as electrodes optimized for high energy storage typically feature denser structures with longer ion diffusion paths that limit rate capability. This limitation manifests as reduced performance under high load conditions, particularly at low states of charge and extreme temperatures where internal resistance increases significantly. The power density limitations necessitate oversizing of battery packs for high-power applications, increasing cost, weight, and volume beyond what would be required if fundamental rate capabilities were improved.

Fast charging represents a particularly challenging aspect of power density limitations, as consumers increasingly expect rapid recharging capabilities comparable to liquid fuel refilling times. Current fast-charging protocols typically achieve 50-80% state of charge in 20-40 minutes under ideal conditions, but these rates often accelerate degradation through lithium plating and increased thermal stress that reduce overall lifespan. The development of truly rapid charging capabilities (5-10 minutes for full charge) requires fundamental improvements in electrode architecture, electrolyte conductivity, and thermal management systems to accommodate the immense power demands without compromising safety or durability. These challenges illustrate the complex interdependencies between various battery performance parameters and the difficulty of advancing one characteristic without affecting others negatively.

Table: Key Performance Limitations of Current Lithium Battery Packs

| Performance Parameter | Current Status | Target Improvement | Primary Challenges |

|---|---|---|---|

| Energy Density (Wh/kg) | 250-300 (cell), 150-200 (pack) | 400-500 (cell), 300-350 (pack) | Material limitations, packaging efficiency |

| Fast Charging Time | 20-40 minutes (50-80% SOC) | 5-10 minutes (80%+ SOC) | Lithium plating, thermal management |

| Cycle Life | 500-1000 cycles (to 80% capacity) | 2000-3000 cycles (to 80% capacity) | Degradation mechanisms, interface stability |

| Cost ($/kWh) | $130-150 (pack level) | <$100 (pack level) | Material costs, manufacturing complexity |

| Temperature Range | -20°C to 45°C (optimal) | -40°C to 60°C (full performance) | Electrolyte limitations, internal resistance |

Safety Concerns and Risk Management

Thermal Runaway and Fire Safety

Thermal runaway represents the most severe safety concern for lithium battery packs, occurring when internal heat generation exceeds dissipation capabilities, creating a dangerous positive feedback loop that can lead to fire or explosion. This phenomenon typically initiates through various mechanisms including internal short circuits, overcharging, mechanical damage, or manufacturing defects that create localized heating sufficient to trigger exothermic decomposition reactions in cell components. Once initiated, thermal runaway can propagate rapidly through battery packs, particularly in high-energy-density configurations where cells are packed closely together with minimal thermal barriers. The prevention and containment of thermal runaway requires sophisticated safety systems including advanced battery management, thermal monitoring, physical separation, and cooling mechanisms that add complexity and cost while reducing overall energy density.

The electrolyte composition in most lithium batteries presents particular safety challenges due to the flammability of organic carbonate solvents used to achieve high voltage stability and conductivity. These flammable electrolytes can ignite when exposed to high temperatures during thermal runaway, exacerbating the situation and potentially causing secondary fires in surrounding materials. The development of non-flammable or reduced-flammability electrolytes represents an active research area, though these alternatives typically involve trade-offs in ionic conductivity, viscosity, and compatibility with electrode materials that have limited commercial implementation thus far. Safety systems must also address external abuse conditions including crash scenarios in vehicles, penetration damage, and external short circuits that could potentially bypass electronic protection systems, requiring robust mechanical design and redundant safety mechanisms.

Manufacturing Defects and Quality Consistency

The manufacturing processes for lithium battery cells and packs involve numerous precise steps where minor variations or defects can lead to significant safety implications during operation. Electrode coating inconsistencies, separator damage, contamination particles, or improper welding can create latent defects that may not appear during initial testing but manifest later as internal short circuits or increased degradation rates. The increasingly high-speed automation of battery manufacturing improves consistency but also introduces new challenges regarding defect detection and process control at production volumes reaching millions of cells per day. These manufacturing challenges necessitate sophisticated quality control systems including automated optical inspection, X-ray imaging, and electrical testing that add cost and complexity while still potentially missing subtle defects that could cause field failures.

The trend toward higher energy densities exacerbates manufacturing challenges by reducing tolerance for imperfections and increasing the severity of consequences when failures occur. Electrodes become thinner and more fragile, separators become thinner to reduce internal resistance, and overall designs incorporate smaller safety margins to maximize performance characteristics. These developments require corresponding advances in manufacturing precision, material purity, and quality assurance methodologies to maintain acceptable safety levels despite the increased sensitivity to defects. The industry continues to develop improved manufacturing technologies including dry electrode processing, defect detection algorithms, and statistical process control methods that enhance consistency while reducing the incidence of safety-critical defects throughout production processes.

Cost and Economic Challenges

Material Costs and Supply Chain Vulnerabilities

The cost structure of lithium battery packs remains heavily influenced by raw material expenses that account for 50-70% of total cell costs, creating vulnerability to price fluctuations and supply chain disruptions. Critical materials including lithium, cobalt, nickel, and copper have experienced significant price volatility driven by increasing demand, geopolitical factors, and supply concentration in specific geographical regions. Cobalt presents particular concerns due to its high cost, ethical sourcing challenges, and significant price volatility that complicate long-term planning and cost reduction efforts. While recent cathode chemistry developments have reduced cobalt content significantly, complete elimination often involves performance trade-offs that limit application suitability, particularly for high-energy-density requirements.

Lithium itself has experienced substantial price increases and volatility as demand growth outpaces supply expansion, though new extraction technologies and discovered resources may alleviate these pressures over the medium to long term. The geographical concentration of lithium production in Australia, Chile, and China creates supply chain vulnerabilities and potential geopolitical risks that could disrupt availability or significantly increase costs during periods of trade tension or export restrictions. These material cost challenges drive research into alternative chemistries with reduced critical material requirements, including lithium iron phosphate (LFP), manganese-rich cathodes, and eventually post-lithium technologies that utilize more abundant elements. However, these alternatives typically involve performance compromises that limit their suitability for applications requiring maximum energy density or specific performance characteristics.

Manufacturing Complexity and Capital Intensity

The manufacturing processes for advanced lithium battery packs involve numerous complex steps requiring precise control and significant capital investment in specialized equipment. Electrode manufacturing requires precise coating, drying, and calendering processes with tight tolerance controls to ensure consistent performance and longevity. Cell assembly involves sophisticated automation for electrode stacking, separator placement, electrolyte filling, and sealing operations that must maintain strict cleanliness standards to prevent contamination. These manufacturing complexities contribute significantly to overall costs while creating barriers to entry that concentrate production capability among a relatively small number of large manufacturers with sufficient capital and technical expertise.

The formation and testing processes represent particularly time-consuming and expensive aspects of battery manufacturing, requiring specialized equipment that occupies substantial factory space while adding limited direct value to the final product. These processes typically involve multiple charge-discharge cycles under controlled conditions to stabilize the solid-electrolyte interphase and identify defective cells before integration into packs. Reducing formation time without compromising quality represents an active area of process development that could significantly reduce manufacturing costs and increase throughput. The capital intensity of battery manufacturing facilities continues to increase as production scales and technology advances, with modern gigafactories requiring investments of $2-5 billion for capacities of 30-50 GWh annually, creating significant financial barriers and economic risks for new market entrants.

Environmental and Sustainability Issues

Resource Extraction and Lifecycle Impacts

The environmental footprint of lithium battery packs extends beyond operational emissions to include significant impacts from raw material extraction, manufacturing processes, and end-of-life management. Lithium extraction typically involves water-intensive processes whether through brine evaporation in salt flats or hard rock mining, creating potential environmental concerns regarding water usage, chemical contamination, and ecosystem disruption in sensitive areas. Cobalt mining presents well-documented ethical and environmental challenges, particularly in artisanal mining operations where safety standards and environmental protections may be inadequate. These extraction impacts necessitate improved mining practices, material recycling, and alternative chemistry development to reduce overall environmental consequences throughout the battery lifecycle.

The manufacturing phase contributes substantially to the carbon footprint of lithium batteries through energy-intensive processes including material synthesis, electrode drying, and cell formation that often utilize electricity from fossil fuel sources. The carbon footprint of battery production varies significantly by manufacturing location and energy source, with estimates ranging from 60-200 kg CO2 equivalent per kWh of battery capacity depending on these factors. Reducing this manufacturing footprint requires transition to renewable energy sources, process efficiency improvements, and material innovations that lower energy requirements during production. These environmental considerations increasingly influence purchasing decisions and regulatory frameworks as consumers and policymakers grow more concerned about the complete lifecycle impacts of energy storage technologies.

Recycling Challenges and Circular Economy Implementation

Despite growing recognition of its importance, lithium battery recycling remains technically challenging and economically marginal compared to primary material production, limiting implementation scale and effectiveness. Current recycling rates for lithium batteries remain below 5% globally, with most end-of-life batteries disposed in landfills or stored indefinitely rather than processed for material recovery. The complex composition of lithium batteries, varying chemistries, and safety concerns regarding spent battery handling create significant barriers to efficient recycling that recovers high-value materials with minimal energy input and environmental impact. Developing effective recycling infrastructure requires coordinated efforts across multiple stakeholders including manufacturers, recyclers, policymakers, and consumers to create economically viable systems that maximize material recovery.

The implementation of circular economy principles for lithium batteries faces numerous challenges including collection logistics, transportation safety regulations, disassembly difficulties, and economic competition with virgin materials. Battery designs that facilitate disassembly and material separation could significantly improve recycling economics but often conflict with performance optimization and manufacturing efficiency priorities. Regulatory frameworks increasingly mandate recycling requirements and extended producer responsibility, though these measures vary significantly by region and implementation effectiveness. Advances in recycling technologies including direct cathode regeneration, hydrometallurgical processes, and automated disassembly systems promise improved economics and environmental performance, though widespread implementation will require substantial investment and coordination across the global battery industry.

Technological and Infrastructure Limitations

Charging Infrastructure and Grid Integration

The widespread adoption of battery-powered systems particularly in transportation faces limitations related to charging infrastructure availability, capability, and grid integration challenges. Current charging infrastructure remains inadequate in many regions, with insufficient deployment rates to support rapidly growing electric vehicle adoption and varying standards that create compatibility challenges. Even where physical infrastructure exists, grid connection limitations often restrict maximum charging power, particularly for fast-charging stations that require substantial electrical capacity that may not be available without expensive upgrades. These infrastructure limitations create practical barriers to adoption that extend beyond battery technology itself, requiring coordinated investment and planning across multiple sectors including energy, transportation, and urban development.

The grid integration of numerous large battery systems presents additional challenges regarding power quality, load management, and infrastructure capacity that must be addressed to support widespread electrification. Simultaneous charging of multiple high-power devices can create localized demand peaks that strain distribution infrastructure not designed for such loads, potentially requiring expensive upgrades or sophisticated management systems to mitigate impacts. Vehicle-to-grid and other bidirectional charging concepts offer potential solutions but introduce additional complexity regarding battery degradation, compensation mechanisms, and standardization that must be resolved before widespread implementation. These infrastructure challenges illustrate how battery technology advancement must occur within a broader ecosystem context where limitations in one area can constrain the benefits of improvements in another.

Standardization and Compatibility Issues

The lithium battery industry continues to struggle with standardization challenges that create compatibility issues, increase costs, and slow innovation adoption across different applications and regions. Cell form factors, electrical connectors, communication protocols, and safety standards vary significantly between manufacturers and applications, limiting interoperability and creating market fragmentation that reduces economies of scale. These standardization issues particularly affect emerging applications and smaller manufacturers who must navigate multiple incompatible systems or develop custom solutions that increase complexity and cost. The lack of standardization also complicates recycling and second-life applications where batteries from different sources must be processed or repurposed using adaptable systems that can handle diverse configurations.

The rapid pace of technological innovation further complicates standardization efforts as new technologies often require different form factors, management approaches, or safety considerations that may not align with existing standards. This tension between innovation and standardization creates challenges for policymakers and standards organizations who must balance the need for stability with the benefits of technological progress. International harmonization of standards remains particularly challenging due to different regulatory approaches, market conditions, and industrial policies across major economic regions including North America, Europe, and Asia. Addressing these standardization challenges requires increased cooperation among stakeholders including manufacturers, users, policymakers, and standards organizations to develop flexible frameworks that support innovation while maintaining necessary compatibility and safety requirements.

Future Improvement Pathways and Research Directions

Material Innovations and Chemistry Advancements

The future improvement of lithium battery packs will likely involve numerous material innovations addressing specific limitations while maintaining or enhancing overall performance characteristics. Solid-state electrolytes represent perhaps the most promising advancement, potentially offering improved safety, higher energy density, and longer cycle life through the elimination of flammable liquid electrolytes and enablement of lithium metal anodes. Numerous technical challenges remain regarding interface stability, manufacturing scalability, and cost effectiveness, though progress continues toward commercial implementation within the next 3-5 years. Alternative cathode materials including lithium-rich manganese-based oxides, disordered rock salts, and anion-redox systems offer potential for significant energy density improvements beyond current nickel-rich NMC formulations, though these often involve trade-offs in rate capability, voltage fade, and manufacturing complexity.

Silicon and lithium metal anode technologies continue to advance toward commercial viability, offering substantial improvements in energy density compared to conventional graphite anodes. Silicon-dominant anodes face challenges regarding volume expansion, initial coulombic efficiency, and cycle life that require sophisticated engineering solutions including nanostructuring, advanced binders, and electrolyte additives to address effectively. Lithium metal anodes present even greater challenges regarding dendrite formation, interface stability, and manufacturing safety that necessitate fundamental advances in electrolyte chemistry, protective layers, and cell design. These material innovations collectively promise substantial improvements across multiple performance parameters, though their commercial implementation requires overcoming significant technical hurdles and demonstrating reliability under real-world conditions.

System-Level Optimization and Integration

Beyond individual component improvements, system-level optimization offers substantial opportunities for enhancing lithium battery pack performance, safety, and cost effectiveness. Advanced thermal management systems utilizing phase change materials, direct cooling, and predictive control algorithms can maintain optimal operating temperatures while minimizing energy consumption and complexity. Structural battery concepts that integrate energy storage directly into product structures offer weight and space savings particularly valuable for transportation applications where efficiency premiums are high. These system-level approaches require multidisciplinary optimization across electrical, thermal, mechanical, and control domains to achieve synergistic improvements that exceed what component-level advances alone can accomplish.

The integration of intelligence and connectivity into battery systems enables adaptive management based on usage patterns, environmental conditions, and predictive analytics that optimize performance while extending lifespan. These smart battery systems can communicate with chargers, loads, and grid management systems to coordinate operation for maximum efficiency and minimum impact. The development of comprehensive digital twins that virtually represent physical battery systems enables advanced diagnostics, prognosis, and optimization without requiring physical experimentation. These system-level advancements complement material innovations to create comprehensive solutions that address multiple challenges simultaneously, though they require sophisticated software development, validation methodologies, and security considerations to implement effectively across diverse applications and operating environments.

-

May.2026.02.127.4V LiPo Battery — A Practical Guide (2S Li-Po / 7.4V)Learn More

May.2026.02.127.4V LiPo Battery — A Practical Guide (2S Li-Po / 7.4V)Learn More -

May.2026.02.10Lithium Polymer Battery Supply Chain Explained: From Raw Materials to Custom Power SolutionsLearn More

May.2026.02.10Lithium Polymer Battery Supply Chain Explained: From Raw Materials to Custom Power SolutionsLearn More -

May.2026.02.097.2V Li-ion Battery Pack – A Complete Technical & Application GuideLearn More

May.2026.02.097.2V Li-ion Battery Pack – A Complete Technical & Application GuideLearn More -

May.2026.02.06Lithium-Ion Battery Energy Density: How Much Energy Can We Really Store?Learn More

May.2026.02.06Lithium-Ion Battery Energy Density: How Much Energy Can We Really Store?Learn More -

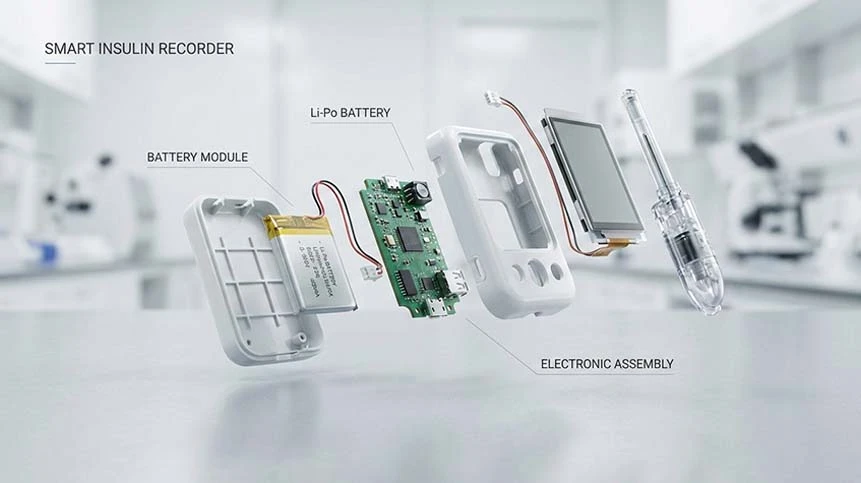

May.2026.02.05Smart Insulin Recorder Battery: Powering Accurate Diabetes Management DevicesLearn More

May.2026.02.05Smart Insulin Recorder Battery: Powering Accurate Diabetes Management DevicesLearn More