Lithium ion problem cause' analysis and solution

You often encounter lithium ion problem when you rely on these batteries for daily use. Manufacturing defects, impurities such as copper particles, and internal short circuits can compromise safety and performance. You may notice issues like capacity loss, internal passivation, thermal runaway, voltage imbalance, and battery expansion.

Common lithium-ion battery problems include:

- Safety risks from defects and impurities

- Internal short circuits

- Accelerated degradation and thermal runaway

Each lithium battery issue has unique causes and solutions, which you will find explained simply in the next sections.

Key Takeaways

- Regularly monitor your lithium-ion batteries to detect voltage imbalances early. This practice helps prevent serious performance and safety issues.

- Use a smart battery management system to avoid overcharging. This system can monitor voltage and current, reducing the risk of overheating and thermal runaway.

- Store lithium-ion batteries in cool, dry places to minimize expansion and capacity loss. Proper storage extends battery life and maintains safety.

- Choose chargers that are compatible with your lithium-ion batteries. Using the right charger prevents damage and reduces the risk of explosion.

- Consult a battery specialist if you notice swelling or other signs of damage. Early intervention can prevent further issues and ensure safety.

Lithium Ion Problem: Voltage Imbalance

Description

Voltage imbalance is a common lithium ion problem that affects the performance and safety of lithium-ion battery packs. When you connect multiple cells in series to achieve higher voltage, each cell may not charge or discharge evenly. Some cells reach full charge while others remain undercharged or become overcharged. This uneven voltage distribution can cause display errors, reduce battery life, and increase the risk of overcharge-related safety incidents. You often see voltage imbalance in high-power applications, such as electric vehicles and grid energy storage systems, where hundreds or thousands of lithium-ion batteries operate together.

Tip: Regular monitoring helps you detect voltage inconsistencies early and prevents serious issues.

Causes

Several factors contribute to voltage imbalance in lithium-ion battery packs:

- Improper battery management system settings can fail to regulate cell voltages accurately.

- Self-discharge of the battery leads to uneven loss of charge among cells, especially during long-term storage.

- Aging causes capacity deviations, making some cells weaker than others.

- Variations in cell capacity and state of charge result in compensatory currents, which can trigger fires or other safety hazards.

- Storage conditions, such as temperature fluctuations, accelerate self discharge and worsen imbalance.

You must pay attention to these causes to maintain the reliability and safety of your lithium battery system.

Solutions

You can address voltage imbalance in lithium-ion battery packs using several proven techniques:

| Technique Type | Description |

|---|---|

| Voltage-based | Equalizes the voltage of each cell to a set threshold using terminal voltage as the main criterion. |

| Passive Equalization | Uses shunt resistors to dissipate extra energy as heat; simple and low-cost but less efficient. |

| Active Equalization | Transfers energy between cells using converters and storage devices for precise individual control. |

- Optimize your battery management system to monitor and balance cell voltages automatically.

- Use cloud resets to recalibrate system settings and correct display errors.

- Apply passive or active balancing techniques to maintain uniform voltage across all cells.

- Implement a proportional-integral controller for passive balancing, which enhances battery life and reliability without complex circuits.

By following these solutions, you can minimize the risk of voltage imbalance and extend the cycle life of your lithium-ion battery system.

Lithium Battery Safety

Overcharging

You face serious safety risks when you overcharge a lithium-ion battery. Overcharging pushes the battery beyond its designed voltage, which can cause overheating and trigger thermal runaway. You may notice signs such as bulging, cracking, popping sounds, or visible gases venting from the battery. These symptoms indicate that the battery is under stress and may fail soon.

| Risk Type | Description |

|---|---|

| Overheating | Overcharging can lead to excessive heat generation in lithium-ion batteries. |

| Thermal Runaway | A chain reaction of uncontrolled heating that can result in fires or explosions. |

| Fire Hazards | The release of flammable gases due to overheating or physical damage can lead to fire risks. |

To prevent overcharging, you should use a smart battery management system (BMS) that monitors voltage and current. Always select chargers compatible with your lithium battery. Avoid leaving devices plugged in overnight. These steps help you maintain safety and reduce the risk of lithium ion problem.

Note: Overcharging lithium-ion batteries can cause internal shorts, leading to rapid heat and energy release. This may result in fires or explosions.

Thermal Runaway

Thermal runaway is one of the most dangerous safety threats in lithium-ion battery systems. When a battery heats up uncontrollably, exothermic reactions occur inside the cell. Separator melting and internal short circuits can accelerate the runaway process. You may observe rising temperatures, hissing sounds, or mechanical damage.

| Mechanisms Leading to Thermal Runaway | Prevention Strategies |

|---|---|

| Exothermic reactions | Use thermally stable electrolytes and shutdown separators. |

| Separator melting | Implement thermal barriers in cell and pack designs. |

| Internal short circuits | Adopt smart BMS for system-level monitoring. |

You can prevent thermal runaway by choosing batteries with advanced materials and thermal barriers. Regularly inspect your lithium-ion battery for physical damage. Smart BMS technology helps you detect early warning signs and maintain safety.

Explosion Risks

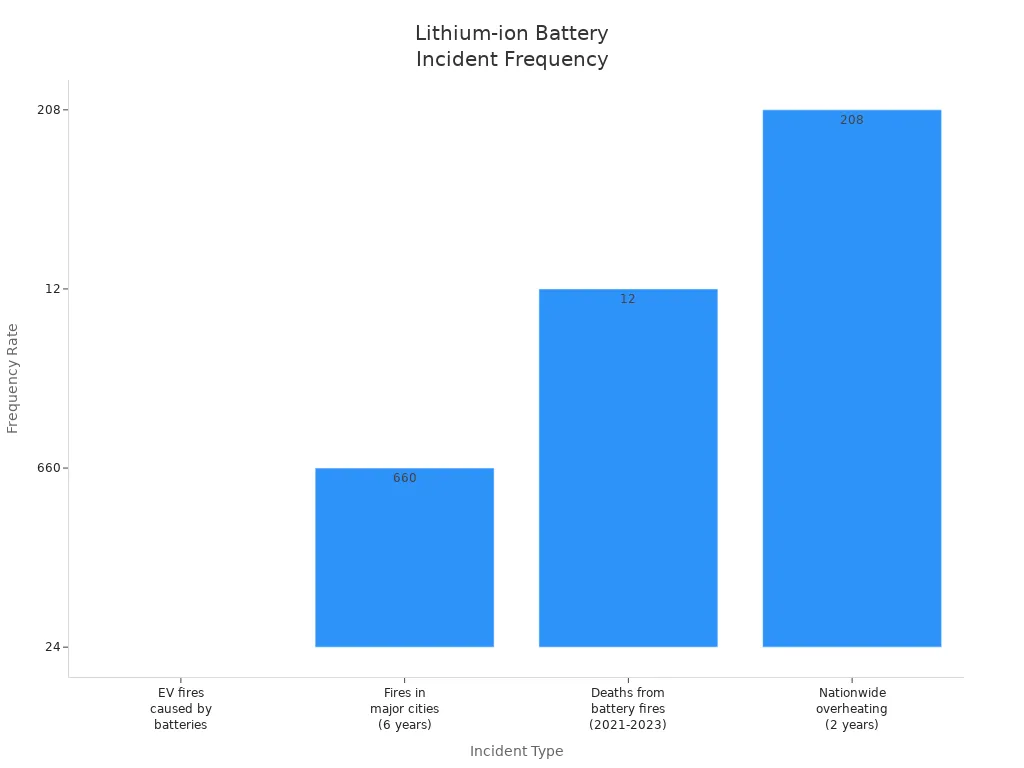

Explosion risks remain a top safety concern for lithium-ion battery users. Although battery explosion incidents are rare, overheating, short circuits, manufacturing defects, and improper use can trigger explosions. In consumer products, over 25,000 overheating or fire incidents have been reported in five years. EV fires caused by lithium-ion batteries account for nearly 24% of reported cases. Major cities have seen more than 660 fires in six years, with at least 12 deaths from lithium-ion battery fires between 2021 and 2023.

To reduce explosion risks, you must follow manufacturer guidelines, avoid exposing batteries to extreme temperatures, and never use damaged or incompatible chargers. Proper handling and regular maintenance ensure the highest level of safety for your lithium-ion battery system.

Lithium-Ion Battery Expansion

Description

You may notice lithium-ion battery expansion when your device starts to bulge or the battery case swells. This issue affects both electric vehicles and portable electronics, such as smartphones and laptops. The electric vehicle sector now holds about 58.5% of the lithium-ion battery market share in 2024. This growth reflects the rising demand for high-performance batteries that support longer driving ranges and faster charging. The global shift toward electric vehicles and the popularity of portable devices drive the need for advanced lithium-ion battery technology. Battery expansion can compromise safety and reduce the lifespan of your lithium-ion battery.

Expansion often signals underlying stress or damage. You should address it quickly to avoid further lithium ion problem.

Causes

Several chemical and physical processes can cause lithium-ion battery expansion:

- Rapid movement of lithium-ions creates physical expansion and contraction in battery materials.

- The materials cannot adjust quickly enough, which leads to significant internal stress.

- Internal stress causes tiny cracks in the electrode materials and accelerates wear in certain battery parts.

You may see battery expansion if you expose your lithium-ion battery to extreme temperatures or overcharge it. Mechanical damage and manufacturing defects also contribute to this issue.

Solutions

You can prevent and manage lithium-ion battery expansion by following these steps:

- Avoid overcharging. Unplug your device once it reaches full charge to prevent overheating.

- Keep your devices cool. Store and use lithium-ion batteries in a cool, dry place to minimize overheating.

- Use appropriate chargers. Always select chargers designed for your specific lithium-ion battery to avoid failures.

- Do not deplete batteries completely. Recharge when the battery drops to around 20% to protect performance.

| Action | Benefit |

|---|---|

| Unplug at full charge | Reduces risk of battery expansion |

| Store in cool place | Maintains battery safety and longevity |

| Use correct charger | Prevents lithium ion problem |

| Recharge at 20% | Preserves lithium-ion battery health |

If you notice battery expansion, stop using the device and seek professional help. Proper handling and regular maintenance help you maintain safety and extend the life of your lithium-ion battery.

Internal Resistance

Description

You may notice your lithium-ion battery does not last as long or deliver power as efficiently as it once did. Internal resistance plays a key role in this decline. This resistance acts as a gatekeeper for power delivery. When internal resistance stays low, your battery can handle power spikes and support demanding digital devices. High internal resistance, however, restricts energy flow. You may see your device shut down early or display low battery warnings even when some charge remains. In real-world applications like electric vehicles and energy storage, internal resistance directly affects efficiency, performance, and the lifespan of your lithium-ion battery. Lower resistance means better performance and longer service life.

Tip: Monitoring internal resistance helps you assess the health and safety of your lithium-ion battery system.

Causes

Several factors can increase internal resistance in your lithium-ion battery. These causes often develop over time or result from environmental conditions.

| Cause of Increased Internal Resistance | Description |

|---|---|

| Electrolyte Conductivity | Lower ionic conductivity in the electrolyte raises resistance. |

| Temperature Effects | Cold temperatures slow ion movement, increasing resistance. |

| State of Charge (SOC) | Resistance rises as the battery discharges deeply. |

| Storage Time | Long storage periods cause aging and higher resistance. |

| Cycling Conditions | High temperatures and deep cycling increase resistance. |

| Structural Design | Poor design of battery components can add resistance. |

| Electrode Material | Electrode quality and size affect resistance. |

| Electrolyte Properties | Viscosity and concentration impact how well the electrolyte wets the electrodes. |

You should pay attention to these factors to maintain optimal performance in your lithium-ion battery.

Solutions

You can take several steps to reduce internal resistance and extend the life of your lithium-ion battery. Engineers use advanced modeling and calibration techniques to predict and manage resistance changes.

| Key Findings | Description |

|---|---|

| Uncertainty Modeling | Models help predict resistance changes and improve battery management. |

| Bayesian Calibration | This approach enhances temperature predictions and reduces uncertainty. |

| Enhanced Resistance Model | Models that account for state of charge and temperature improve accuracy, especially at low charge levels. |

You can also store your lithium battery at moderate temperatures and avoid deep discharges. Regularly check your battery’s health and replace it if resistance rises sharply. These actions help you maintain safety, performance, and reliability in your lithium-ion battery system.

Power Loss

Description

You may notice your lithium-ion battery does not deliver as much energy as expected. Power loss happens when the battery cannot provide its full capacity during use. This issue affects electric vehicles, renewable energy systems, and portable electronics. When power loss occurs, you experience shorter run times, slower device performance, and sometimes unexpected shutdowns. Power loss can also increase the risk of thermal runaway or even battery explosion if not managed properly. You need to understand this problem to maintain safety and extend the life of your lithium-ion battery.

Causes

Several factors contribute to power loss in lithium-ion battery systems:

- Ambient temperature changes can reduce battery performance and energy efficiency.

- High discharge current limits how much energy you can use from the battery.

- Cutoff voltage settings determine how much of the battery’s energy is available before the system shuts down.

Field studies show that lithium plating and the growth of the solid electrolyte interphase (SEI) film are the main reasons for power loss. Lithium plating often happens when you charge the battery at low temperatures or with high current. This process causes significant capacity loss, especially in the early cycles. Over time, SEI film growth becomes the dominant factor, leading to further lithium-ion loss. Improper charging habits, such as charging in cold environments, can make these problems worse.

⚠️ Power loss increases the risk of thermal runaway and explosion, especially if you ignore early warning signs.

Solutions

You can take several steps to reduce power loss and improve the performance of your lithium-ion battery:

- Prevent thermal runaway by monitoring battery temperature and using advanced battery thermal management systems.

- Install cooling systems to keep the battery within a safe temperature range and avoid escalation during thermal runaway.

- Address manufacturing defects and always use proper charging methods to prevent overcharging and reduce the risk of explosion.

- Use a time-sequence map to track and understand thermal runaway events at both the cell and system levels.

- Identify and summarize abuse conditions that may trigger thermal runaway, which helps you enhance battery protection.

- Apply strategies at the material, cell, and system levels to limit thermal runaway and improve overall safety.

| Solution Type | Benefit |

|---|---|

| Cooling systems | Prevents overheating and thermal runaway |

| Proper charging | Reduces lithium plating and SEI growth |

| Battery management | Detects early signs of power loss and explosion risk |

By following these solutions, you can minimize power loss, reduce the chance of battery explosion, and ensure your lithium battery operates safely and efficiently.

Low Voltage

Description

You may encounter low voltage in your lithium-ion battery when the cell voltage drops below the recommended threshold. This issue often leads to reduced performance, unexpected shutdowns, or even permanent damage to the battery. Low voltage can increase the risk of explosion, especially if you continue to use or charge the affected cell. In electric vehicles and portable devices, low voltage can compromise safety and reliability. You should always monitor your lithium-ion battery voltage to prevent further complications.

Tip: Early detection of low voltage helps you avoid costly repairs and potential explosion risks.

Causes

Several factors can cause low voltage in a lithium-ion battery. Manufacturers have identified the following leading causes:

| Cause | Explanation |

|---|---|

| Large self-discharge | The cell loses charge quickly, causing a rapid voltage drop. Proper storage can help reduce this. |

| Uneven charging | Inconsistent charging leads to voltage differences. Proper charging methods resolve this issue. |

| Large internal resistance | High resistance may result from long storage, testing errors, or abnormal heating during processing. |

| Improper processing | Manufacturing issues, such as poor welding, increase internal resistance and lower voltage. |

You should pay attention to these factors when diagnosing low voltage problems in your lithium-ion battery.

Solutions

You can resolve low voltage issues in your lithium-ion battery by following best practices:

- Check the voltage after storage to identify large self-discharge early.

- Use proper charging methods to ensure even charging and avoid voltage differences.

- Measure voltage after storage to detect any abnormal drops.

- Inspect for signs of high internal resistance or improper processing, such as unusual heating or visible defects.

Regular maintenance and monitoring help you maintain safety and extend the life of your lithium battery.

If you notice persistent low voltage, consult a battery specialist before continued use. This step protects your device and reduces the risk of explosion.

Improper Processing

Description

Improper processing in lithium-ion battery manufacturing can lead to serious failures and safety risks. You may encounter problems such as internal short circuits, rapid self-discharge, and even explosion. These issues often arise when manufacturers do not follow strict quality control standards. Improper handling during assembly, contamination, or poor design can compromise the reliability of your lithium-ion battery. You need to understand how these failures occur to protect your devices and ensure long-term safety.

If you notice swelling, overheating, or sudden power loss, improper processing might be the root cause.

Causes

Manufacturing errors and poor process control create many risks for lithium-ion battery systems. The following table highlights the most common types of improper processing and their consequences:

| Type of Improper Processing | Description |

|---|---|

| Impurities causing short circuits | Transition metal impurities in the positive electrode slurry can pierce the separator or form lithium dendrites, leading to internal short circuits. |

| Formation of lithium dendrites | Dendrites can develop due to uneven local charge during cycling, penetrating the separator and causing internal short circuits. |

| Improper design or excessive local pressure | Unreasonable design or excessive pressure during assembly can also result in internal short circuits. |

| Internal short circuits | These can lead to self-discharge, capacity decay, and thermal runaway. |

| Short circuit between current collectors | Untrimmed metal objects can pierce separators or electrodes, causing contact between positive and negative current collectors. |

| Diaphragm failure | Aging or corrosion of the diaphragm can lead to micro-contact between electrodes, resulting in severe local heating and thermal runaway. |

You also face risks from equipment failures in the production line. Mixing systems, drying ovens, and coating plants can create explosive atmospheres if not managed properly. Electrolyte filling and extraction systems may leak, releasing toxic gases or causing fires.

Solutions

You can prevent improper processing in lithium-ion battery manufacturing by following proven strategies:

- Embrace preventative measures instead of reacting to hazards after they occur.

- Implement robust battery design and enforce stringent manufacturing standards.

- Establish safety protocols and advanced monitoring systems to detect problems early.

- Avoid charging and discharging cells beyond their specified safe limits.

- Prevent high-rate charging in elevated temperature conditions.

- Do not over-discharge cells below their specified endpoint voltage.

Store your lithium battery in a cool, dry environment between 15°C and 25°C. This practice helps prevent electrolyte breakdown and reduces the risk of explosion. Use smart chargers to maintain safe charging cycles. Regularly inspect your lithium-ion battery for damage and replace defective units immediately.

Consistent quality control and regular inspections help you avoid costly failures and protect your devices from explosion and other hazards.

Capacity Loss & Passivation

Description

You may notice your lithium-ion battery loses capacity over time, even with careful use. This problem, known as capacity loss, often appears as shorter run times and reduced performance. Passivation refers to the formation of a protective layer inside the battery, which slows down chemical reactions but also restricts energy flow. The solid electrolyte interphase (SEI) layer forms on the anode and acts as a barrier. While it improves electrochemical stability, it also consumes active lithium and reduces the battery’s ability to deliver power. You need to understand these processes to maintain safety and prevent unexpected failures or explosion risks.

Tip: Regular monitoring of your lithium-ion battery helps you detect early signs of capacity loss and passivation.

- Lithium-ion batteries degrade over time due to calendar aging, which involves unavoidable chemical side reactions.

- The growth of the SEI is a primary side reaction that acts as a passivating film on the anode, but it continues to grow and consume lithium ions throughout the battery's life.

- Cycling-based degradation occurs during charging and discharging, accelerating SEI growth and loss of lithium inventory (LLI).

- Manufacturers often rate batteries based on their ability to complete a certain number of cycles before degrading to 80% capacity, commonly around 1,000 full cycles.

Causes

You face capacity loss and passivation in your lithium-ion battery due to several chemical and physical factors. The SEI layer plays a crucial role in both processes. As the SEI grows, it enhances stability but restricts electron movement, leading to further electrolyte reduction. This process consumes active lithium from the electrolyte, which reduces the battery’s capacity. Researchers use advanced modeling techniques to study the kinetics and thermodynamics of SEI growth, showing how complex these reactions can be. You should pay attention to these causes to protect your lithium battery and ensure long-term safety.

Solutions

You can reduce capacity loss and passivation in your lithium-ion battery by following proven strategies. Recent studies have focused on non-aqueous Li-Air batteries, but the findings apply to most lithium-ion systems.

| Aspect | Description |

|---|---|

| Study Focus | Capacity loss in non-aqueous Li-Air batteries due to insoluble product formation |

| Key Findings | Development of approximate formulas to evaluate battery capacity, validated against experiments |

| Parameters Discussed | Surface coverage factor, tortuosity, and Damköhler numbers (Da) |

| Application | Guidelines for air cathode design, analysis, and control |

You should select batteries with optimized cathode designs and monitor surface coverage to minimize passivation. Regular cycling within recommended limits helps slow SEI growth. Store your lithium-ion battery in a cool, dry place to reduce side reactions. If you notice rapid capacity loss, consult a battery specialist for advanced diagnostics and solutions.

You have learned the main causes of lithium-ion battery problems, including inconsistent voltage, high internal resistance, battery expansion, power loss, and explosion risks. You can prevent these issues by storing batteries in cool, dry places, using proper charging methods, and choosing batteries with robust safety features. Regular maintenance and professional inspections help you catch problems early and maintain safety.

Always monitor your batteries for damage or swelling. If you notice any issues, consult an expert for guidance.

| Resource | Description |

|---|---|

| Australian Competition and Consumer Commission | Consumer product safety insights |

| Occupational Safety and Health Administration | Fire and explosion prevention guidelines |

| U.S. Consumer Product Safety Commission | Battery safety status report |

For expert advice or detailed information, call 508-996-4110 or email tom@marinesafetyconsultants.com.

FAQ

What causes lithium-ion batteries to lose capacity quickly?

You often see rapid capacity loss from frequent deep discharges, high temperatures, or improper charging.

Store batteries in cool, dry places and avoid draining them completely to slow down degradation.

How can you prevent lithium-ion battery explosions?

- Use certified chargers.

- Avoid physical damage.

- Monitor battery temperature.

Always follow manufacturer guidelines for charging and storage. Replace damaged batteries immediately.

Why does my lithium-ion battery swell or expand?

| Reason | Solution |

|---|---|

| Overcharging | Unplug at full charge |

| High temperature | Store in cool places |

| Physical damage | Replace battery |

Swelling signals stress or damage. Stop using the battery and seek professional help.

What is the safest way to charge lithium-ion batteries?

You should use a smart charger designed for your battery type.

Charge at room temperature.

Never leave devices plugged in overnight.

These steps help you avoid overheating and extend battery life.

How do you know if your lithium-ion battery needs replacement?

- Short run times

- Swelling or bulging

- Frequent overheating

- Sudden shutdowns

If you notice these signs, replace the battery to maintain safety and performance.

-

May.2026.03.03Sodium Batteries and Lithium-Ion Batteries: Low-End Substitutes or Strategic Complements?Learn More

May.2026.03.03Sodium Batteries and Lithium-Ion Batteries: Low-End Substitutes or Strategic Complements?Learn More -

May.2026.02.27Lithium-Ion Batteries: The Six Constraints Blocking the Path to PerfectionLearn More

May.2026.02.27Lithium-Ion Batteries: The Six Constraints Blocking the Path to PerfectionLearn More -

May.2026.02.25Li-Polymer Battery 5000mAh: Complete Technical & OEM GuideLearn More

May.2026.02.25Li-Polymer Battery 5000mAh: Complete Technical & OEM GuideLearn More -

May.2026.02.24The Unparalleled Advantages of Lithium-Ion Batteries Over Traditional BatteriesLearn More

May.2026.02.24The Unparalleled Advantages of Lithium-Ion Batteries Over Traditional BatteriesLearn More -

May.2026.02.243.6 Volt Battery: Complete Technical Guide for Engineers & BuyersLearn More

May.2026.02.243.6 Volt Battery: Complete Technical Guide for Engineers & BuyersLearn More