Introduction:

I’m the technical lead at A&S Power and I’ve worked with thousands of small lithium battery projects for wearables, medical devices, sensors and consumer IoT. In this guide I’ll explain what “small lithium battery” typically means, walk you through the common chemistries and formats, show typical electrical and mechanical specs, discuss safety and shipping rules you must follow, and give practical tips for sourcing or customizing batteries with clear steps to request a quotation.

What we mean by “small lithium battery” (definition & market context)

When I say “small lithium battery” I refer to rechargeable or primary lithium cells and batteries whose typical form-factors and capacities are optimized for compact devices — coin/coin-cells (CR2032, etc.), thin pouch Li-Po cells used in wearables, small cylindrical cells (e.g., 10440/14500), micro-prismatic modules, and low-capacity packs (from a few mAh up to several Ah). These small batteries are used in products where size, weight and energy density matter more than absolute energy (for example: hearing aids, IoT sensors, wearables, small medical implants/portable diagnostics, small backup modules). Technical overviews and chemistries are well summarized in Battery University’s reference materials.

Market snapshot (high level):

The lithium-ion battery market continues to grow rapidly across segments; small cell demand is driven by consumer electronics and IoT, and materials/production investment is scaling to meet this trend. Industry market reports estimate double-digit CAGR segments for lithium battery markets over the next 5–10 years.

Common chemistries and what they mean for small batteries

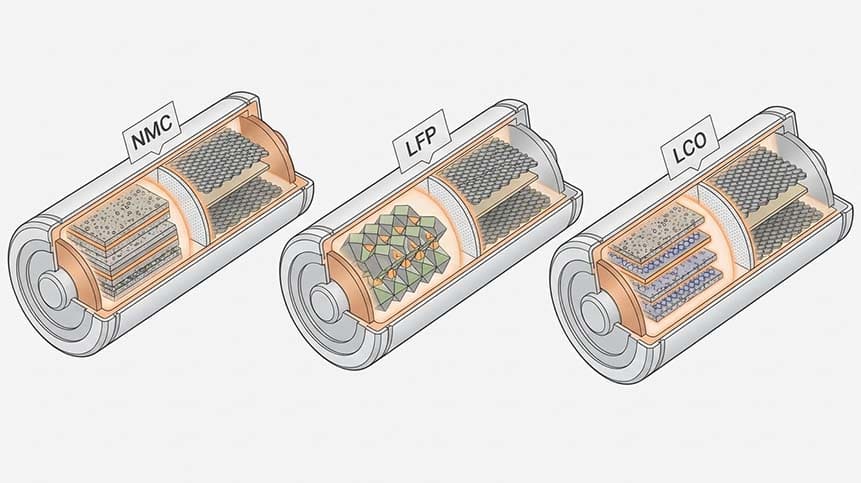

Lithium-ion (rechargeable) family — NMC, LFP, LCO, etc.

-

NMC (Nickel-Manganese-Cobalt): higher energy density, common where energy > cycle life.

-

LFP (Lithium Iron Phosphate): lower nominal voltage but excellent cycle life and thermal stability — used where safety and longevity are priorities.

-

LCO (Lithium Cobalt Oxide): high energy density — typical in small consumer rechargeable cells historically (smartphones), but cost and safety tradeoffs apply.

Battery University provides a useful summary table of lithium chemistries and tradeoffs.

Lithium metal and primary coin cells

Coin cells like CR2032 are commonly primary (non-rechargeable) lithium chemistries with stable voltages and very low self-discharge. They remain popular where long shelf life and tiny size are required.

Li-polymer (pouch) cells

Pouch cells are flexible, thin, and can be shaped for space-constrained devices (wearables, slim medical devices). They can be manufactured at small capacities and are common for custom small battery packs.

Typical specifications — what to look for

Below I list the key specs that almost every engineer or buyer needs when evaluating small lithium batteries.

Electrical specs

-

Nominal voltage: typical Li-ion nominal cell voltages are 3.6–3.7V; LFP is ~3.2V; primary lithium coin cells are ~3.0V.

-

Capacity (mAh): small coin cells: 20–240 mAh (e.g., CR2032 ~225 mAh nominal in small loads), pouch cells for wearables: typical 50–1000 mAh depending on footprint.

-

C-rate / continuous discharge: small packs often need high-pulse capability for wireless transmissions — always request the recommended max continuous and pulse discharge rates from the manufacturer.

-

Internal resistance (mΩ): important for high-current pulses; higher internal resistance = larger voltage drop under load.

Mechanical & environmental specs

-

Dimensions/weight: critical for product integration — ask suppliers for 2D drawings and 3D STEP files.

-

Operating temperature range: small batteries for medical or industrial applications may require extended temperature ratings.

-

Swelling behaviour: pouch cells can swell during aging — design mechanical allowance. Battery University explains swelling and charging behaviours in detail.

Quick selection checklist

-

Define required nominal voltage and peak/continuous current.

-

Define required capacity (mAh) and runtime target.

-

Decide chemistry preference (LFP if safety/life critical, NMC/LCO if energy density matters).

-

Confirm mechanical envelope & connector type.

-

Confirm certifications required for your market (CE, UN transport approvals, IEC/UL if medical).

-

Ask supplier for sample cells, datasheet, safety data sheet (SDS), and test reports.

Data table — typical small lithium battery types

| Type | Example | Nominal Voltage | Capacity | Applications |

|---|---|---|---|---|

| Coin Cell | CR2032 | 3.0V | 25–225 mAh | Watches, sensors |

| Pouch Cell | 30×20×4 mm | 3.7V | 50–1000 mAh | Wearables, medical |

| Cylindrical | 14500 | 3.7V | 200–800 mAh | Portable devices |

Data sources and chemistry tables summarized from industry references. For detailed chemistries and comparative tables, see summaries at Battery University.

Safety, testing and shipping

Safety is non-negotiable. Small batteries still present thermal runaway and transport hazards if mishandled, shorted, or improperly packaged.

Testing & certification I recommend

-

IEC 62133 (safety for portable cells and batteries) for many markets.

-

UN 38.3 cell/battery transport tests (vibration, thermal, shock, altitude, etc.) for shipping approval.

-

CE / RoHS where applicable for EU consumer products.

Ask suppliers for test reports and certificates — never accept verbally stated compliance without documents.

Shipping rules you must know (practical points)

-

Lithium batteries are regulated by IATA/ICAO and DOT/PHMSA for air and ground transport. For many small batteries, special provisions (e.g., PI 965/PI 966/PI 967/PI 968) define packaging, state of charge limits (power banks often limited to ≤30% SoC in certain shipment modes), and whether the cells can travel on passenger aircraft. See IATA’s Lithium Battery Guidance Document for details.

-

The U.S. Pipeline and Hazardous Materials Safety Administration (PHMSA) publishes practical guides for shippers of lithium batteries — follow packaging, marking, and hazard communication rules.

Practical shipping tips I follow when sending sample small batteries internationally: use manufacturer-provided UN approved packaging when available, include SDS and test reports, and mark state of charge if required. For power banks or assembled devices, check the exact PI numbers and whether Section IA/IB/II applies.

Charging strategy & BMS considerations

For reliable operation and longevity you must match charging to the cell chemistry and include proper protection:

-

Battery management: For small single-cell packs, a PCM (protection circuit module) that handles over-charge, over-discharge, over-current and short-circuit protection is standard. For multi-cell configurations, use a full BMS with cell balancing.

-

Charge profile: Most Li-ion cells require a CC-CV charge profile (constant current until cell reaches charge voltage, then constant voltage until current tapers) — overcharge is dangerous. Detailed charging notes are available in Battery University charging guides.

-

SoC and shipping / storage: For shipping and long-term storage, lower SoC (e.g., ~30–40%) reduces stress and is often mandated for air transport of spare batteries.

Sourcing and supplier qualification

When I source small lithium batteries, I evaluate suppliers across the following axes:

-

Quality & testing evidence — Do they provide cell datasheets, UN 38.3 reports, IEC 62133 and manufacturer test logs?

-

Manufacturing capacity & lead time — Small-run custom projects need clear MOQ and ramp-up plans.

-

Customization services — Will they handle tabning, connector soldering, PCM integration, UL/IEC testing coordination?

-

Regulatory support — Can they supply packaging, SDS, and paperwork for shipments?

-

After-sales & failure analysis — Do they offer warranty, failure investigation, and corrective actions?

Practical procurement workflow I recommend (steps to request a quote):

-

Prepare a one-page specification: nominal voltage, capacity target, max continuous current, max pulse, mechanical envelope, required certifications, target annual volume.

-

Send RFQ to 3–5 qualified suppliers with NDA if IP sensitive.

-

Request DATASHEET, SDS, UN 38.3, IEC 62133, and sample pricing.

-

Order engineering samples for verification; run your own environmental and cycle tests.

-

Move to small pilot order before mass production.

Real-world design examples

Wearable fitness tracker

-

Constraint: ultra-thin 50 mAh pouch battery, peak bursts 500 mA for BLE transmissions, required 2 years standby.

-

Solution highlights: choose high-C thin pouch, PCM for single-cell protection, mechanical holder with allowance for up to 5% swelling, validate with 500 cycle test at 25°C and 40°C storage tests.

Portable medical diagnostic device

-

Constraint: medical safety and long life, IEC/ISO requirements.

-

Solution highlights: prefer LFP chemistry where possible for added thermal stability, use a BMS with logging for traceability, and require supplier to provide IEC 62133 + recall insurance terms.

Pricing & lead time expectations

Pricing for small lithium batteries varies by chemistry, capacity, certifications and volumes. Market reports show significant variations by segment and rising material costs can affect pricing. As a practical benchmark: small coin cells and commodity pouch cells at high volumes are lower cost per mAh; custom engineered small packs with medical certifications will be materially higher due to testing and documentation. See broad market forecasts for industry trends.

Frequently Asked Questions (FAQ)

Can I ship small lithium batteries by air?

Yes — but only under strict conditions and packaging rules. Air transport is governed by IATA/ICAO and the applicable Packing Instructions (PI 965/966/968 etc.). Some batteries/quantities are allowed on passenger aircraft under Section II or IA/IB with restrictions; other shipments must travel as cargo or require special approvals. Always confirm the exact PI number with your shipper and provide UN 38.3 and other certificates.

What documents should suppliers provide?

At minimum: cell datasheet, SDS, UN 38.3 test report, IEC 62133 certificate (if applicable), and sample testing data. For medical devices, uploadable test reports and traceability records are typically required.

How long can a small lithium battery be stored?

Storage life depends on chemistry and SOC. Primary lithium coin cells have long shelf life (years). Rechargeable Li-ion/lipo should be stored at ~30–50% SoC in cool, dry conditions for best long-term storage life.

Are pouch cells safe for medical devices?

Yes — pouch cells are widely used in medical and wearable products, but they need careful mechanical design (to allow swelling), a robust protection circuit, and the right chemistry selection. For patient-critical devices, LFP chemistry is often preferred for thermal stability.

How I can help

If you need a custom small lithium battery for a wearable, medical device, or IoT project, you can request a quote here: Contact A&S Power