China Lithium Battery Manufacturer: A Complete Buyer's Guide for Global OEMs

As a China-based lithium battery manufacturer, we have worked with OEM and ODM clients across medical devices, consumer electronics, industrial equipment, and IoT applications for over a decade.

In this guide, I will explain why China dominates the global lithium battery industry, how buyers should evaluate suppliers, and what truly matters when sourcing lithium batteries from China.

This article is designed to directly answer the most common questions asked by global buyers, engineers, and procurement teams, while also providing verifiable data, standards, and best practices.

Why China Is the Global Hub for Lithium Battery Manufacturing

China is not just a lithium battery producer—it is the core of the global lithium battery ecosystem.

Complete Industrial Supply Chain

China offers a vertically integrated supply chain that includes:

-

Cathode and anode material production

-

Cell manufacturing (Li-ion, LiPo, LiFePO4)

-

Battery pack assembly

-

BMS design and firmware

-

Certification testing and logistics

This ecosystem significantly reduces lead time and cost compared to fragmented supply chains in other regions.

Global Market Share and Production Capacity

According to industry data:

-

Over 70% of global lithium-ion battery production is based in China

-

China hosts the world’s largest battery factories, including CATL and BYD

-

China supplies batteries to EV, medical, and consumer brands worldwide

This dominance is driven by scale, automation, and engineering experience.

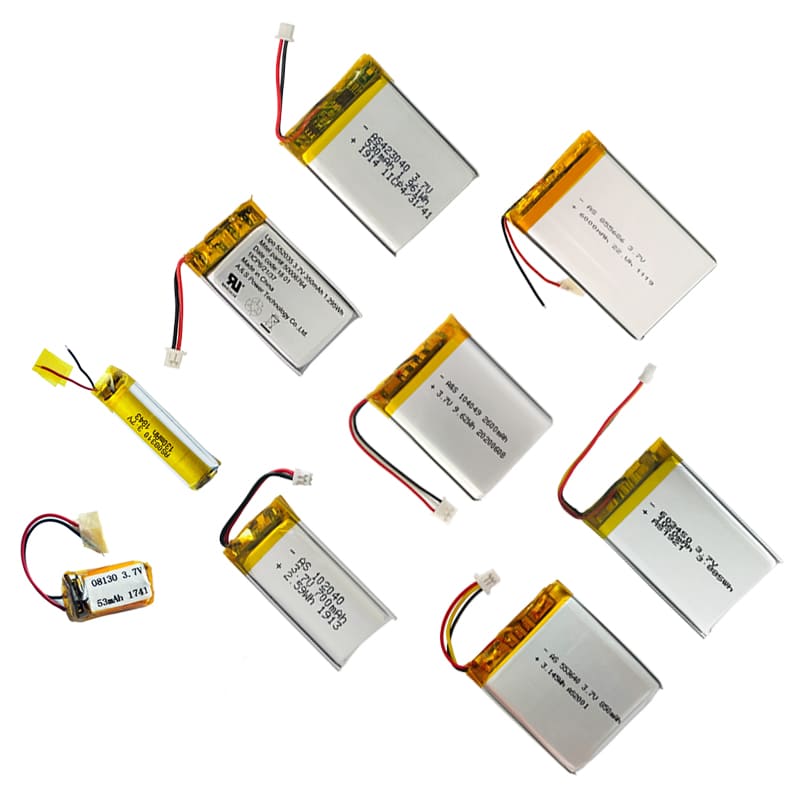

Types of Lithium Batteries Manufactured in China

China lithium battery manufacturers typically support the following categories:

Lithium-Ion Battery Packs (Li-ion)

-

18650 / 21700 / prismatic cell based

-

High energy density

-

Long cycle life

-

Ideal for industrial, medical, and energy storage systems

Lithium-Polymer Battery Packs (LiPo)

-

Ultra-thin and flexible shapes

-

Lightweight design

-

Custom dimensions available

-

Widely used in wearables, medical devices, and consumer electronics

Lithium iron phosphate Battery (LiFePO4)

-

Extremely long cycle life

-

High thermal stability

-

Safer chemistry

Used in:

-

Energy storage

-

Industrial systems

-

Backup power solutions

Application-Specific Custom Battery Packs

We engineer battery packs based on:

-

Voltage & capacity requirements

-

Size and enclosure constraints

-

Connector and cable specifications

-

Charge/discharge current profiles

-

Safety, certification, and lifespan expectations

Custom Lithium Battery Solutions from China

One major advantage of sourcing from China is deep customization capability.

What Can Be Customized?

From our experience, OEM clients typically customize:

-

Cell selection (Samsung, LG, Panasonic, or qualified China cells)

-

Voltage and capacity

-

Battery size and shape

-

Connector and cable type

-

BMS functions (overcharge, temperature, communication)

-

Certifications (UN38.3, IEC 62133, UL, CE)

Customization allows brands to optimize performance, safety, and cost.

Certifications Required for China Lithium Batteries

Any reliable China lithium battery manufacturer must comply with global standards.

Key International Certifications

| Certification | Purpose | Mandatory |

|---|---|---|

| UN38.3 | Transportation safety | Yes |

| IEC 62133 | Consumer & medical safety | Yes |

| UL 2054 / UL 1642 | North American compliance | Market-based |

| CE | European conformity | Yes |

| MSDS | Material safety | Yes |

These certifications ensure batteries can be legally shipped and sold worldwide.

How to Choose a Reliable China Lithium Battery Manufacturer

Not all suppliers are equal. Based on real-world experience, here’s what buyers should evaluate.

Factory Capability vs Trading Company

A real manufacturer should:

-

Own battery assembly lines

-

Provide engineering drawings

-

Offer sample testing

-

Support long-term production

Engineering Support

Strong suppliers provide:

-

Battery pack design review

-

Application analysis

-

Safety validation

-

Lifecycle optimization

Cost Structure of Lithium Batteries from China

What Impacts Pricing?

-

Cell brand and chemistry

-

BMS complexity

-

Certification requirements

-

Order volume

Cost Comparison Table (Indicative)

| Factor | China Manufacturer | Local Supplier |

|---|---|---|

| Unit Cost | Lower | Higher |

| Customization | High | Limited |

| Lead Time | Fast (OEM) | Medium |

| Certification Support | Strong | Varies |

| MOQ Flexibility | Medium–High | Often Low |

Data-Backed Comparison: China vs Other Regions

| Region | Cost | Lead Time | Customization | Certification Support |

|---|---|---|---|---|

| China | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★★ |

| Europe | ★★★ | ★★ | ★★ | ★★★ |

| USA | ★★ | ★★ | ★★ | ★★★ |

China remains the most balanced option for cost, speed, and technical depth.

Quality Control & Reliability Assurance

A reliable China lithium battery factory should provide:

-

Incoming material inspection

-

Aging & cycle testing

-

Overcharge / short-circuit testing

-

Traceability via batch numbers

-

ISO-based QC systems

At A&S Power, every battery pack is tested before shipment, not sampled.

Common Risks When Sourcing Lithium Batteries from China (And How We Solve Them)

Communication Gaps

We provide English-speaking engineering support and documented specs.

Inconsistent Quality

We maintain fixed BOMs and locked production processes.

Certification Delays

We design packs with certification in mind from day one.

FAQ – China Lithium Battery Sourcing

Is it safe to source lithium batteries from China?

Yes, when working with a certified manufacturer that follows international safety and quality standards.

What is the MOQ for custom lithium battery packs?

MOQ varies by design but typically starts from 300–500 packs for OEM projects.

Can China lithium batteries meet EU and US regulations?

Absolutely. Most global lithium battery certifications originate from China-based factories.

How long does custom battery sampling take?

Usually 7–15 working days, depending on complexity.

Final Thoughts: Why We Recommend Sourcing Lithium Batteries from China

From our first-hand experience as a China lithium battery manufacturer, the combination of engineering depth, supply chain efficiency, certification expertise, and cost control makes China the most strategic sourcing destination for global OEMs.

If you are looking for a long-term, compliant, and scalable lithium battery partner, China remains the smartest choice.

-

May.2026.03.03Sodium Batteries and Lithium-Ion Batteries: Low-End Substitutes or Strategic Complements?Learn More

May.2026.03.03Sodium Batteries and Lithium-Ion Batteries: Low-End Substitutes or Strategic Complements?Learn More -

May.2026.02.27Lithium-Ion Batteries: The Six Constraints Blocking the Path to PerfectionLearn More

May.2026.02.27Lithium-Ion Batteries: The Six Constraints Blocking the Path to PerfectionLearn More -

May.2026.02.25Li-Polymer Battery 5000mAh: Complete Technical & OEM GuideLearn More

May.2026.02.25Li-Polymer Battery 5000mAh: Complete Technical & OEM GuideLearn More -

May.2026.02.24The Unparalleled Advantages of Lithium-Ion Batteries Over Traditional BatteriesLearn More

May.2026.02.24The Unparalleled Advantages of Lithium-Ion Batteries Over Traditional BatteriesLearn More -

May.2026.02.243.6 Volt Battery: Complete Technical Guide for Engineers & BuyersLearn More

May.2026.02.243.6 Volt Battery: Complete Technical Guide for Engineers & BuyersLearn More