Lithium LiPo Battery for Medical and Health Monitoring Equipment

Introduction: Powering the Next Generation of Medical Electronics

In recent years, medical and health monitoring equipment has rapidly shifted toward portable, wearable, and home-use designs. From compact nebulizers used by asthma patients to continuous ECG patches worn for days, modern healthcare devices demand power solutions that are small, lightweight, stable, and reliable.

Based on our experience working with OEM and ODM medical device manufacturers, lithium polymer (LiPo) batteries have become one of the most widely adopted power technologies for medical and near-medical applications. Their thin profile, flexible form factor, and stable electrical performance make them particularly well suited for patient-facing devices, where comfort, safety, and reliability are non-negotiable.

In this guide, we explain why LiPo batteries are favored, how they are used across medical and health monitoring equipment, how to select the right specifications, and what standards and certifications matter most when building compliant medical products.

Medical and Health Monitoring Use Cases for LiPo Batteries

LiPo batteries are now found across a wide range of regulated and semi-regulated healthcare devices. Below are the most common application categories.

Portable Nebulizers

Portable nebulizers have transitioned from bulky AC-powered machines to compact, battery-operated devices for home and travel use.

Battery requirements:

-

Stable discharge for consistent aerosol output

-

Moderate capacity (typically 1500–3000mAh)

-

Lightweight and compact internal space

Why LiPo works:

LiPo pouch cells offer high energy density in a flat shape, allowing manufacturers to design slim, handheld enclosures without compromising treatment time.

Blood Glucose Meters

Modern glucose meters prioritize portability, fast response, and long standby time.

Battery requirements:

-

Low self-discharge

-

Stable voltage at low current draw

-

Compact size

Typical battery range:

-

300–1000mAh single-cell LiPo

LiPo batteries support long shelf life and predictable discharge behavior, critical for devices that may sit idle between measurements.

Electronic Thermometers

Electronic and infrared thermometers often operate on very small power budgets, yet must remain accurate and reliable.

Why LiPo is used:

-

Ultra-thin cells (as thin as 4 mm)

-

High cycle stability at low load

-

Minimal form factor constraints

These advantages allow designers to create ergonomic, pocket-sized products while maintaining measurement accuracy.

Smart Blood Pressure Monitors

Smart blood pressure monitors increasingly integrate:

-

Bluetooth connectivity

-

Mobile app synchronization

-

Rechargeable batteries

Battery needs:

-

800–2000mAh capacity

-

High reliability across repeated charge cycles

-

Stable output during motor-driven cuff inflation

LiPo batteries provide consistent performance even under short bursts of higher current, which is essential for accurate readings.

ECG Patches and Wearable Health Devices

Wearable medical electronics represent one of the fastest-growing segments in healthcare technology.

Examples include:

-

ECG monitoring patches

-

Heart rate and SpO₂ wearables

-

Sleep and activity health trackers

Key battery requirements:

-

Ultra-thin thickness (4–6 mm typical)

-

Flexible or contoured pouch designs

-

Long cycle life and low self-discharge

-

High safety and traceability

Industry research consistently highlights LiPo pouch cells as a leading battery option for wearable medical electronics, due to their mechanical flexibility and patient comfort advantages.

Why Lithium LiPo Batteries Are Preferred in Medical Devices

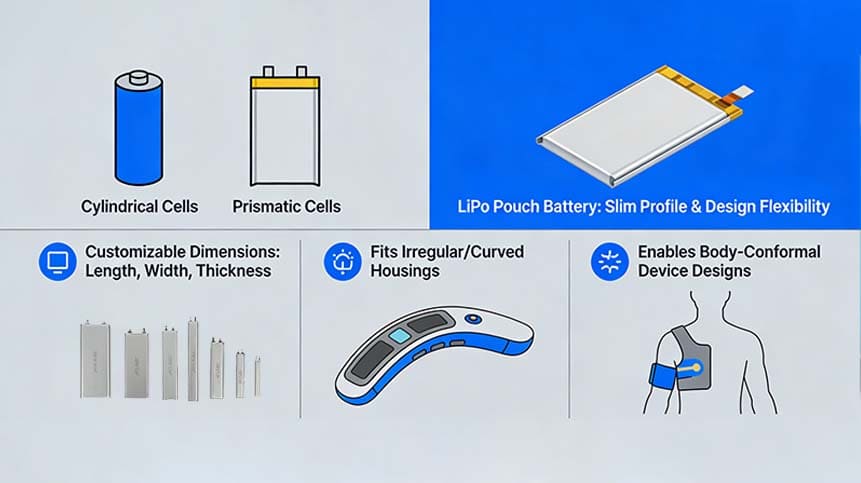

Slim Profile and Design Flexibility

Unlike cylindrical or prismatic cells, LiPo pouch batteries:

-

Can be customized in length, width, and thickness

-

Fit irregular or curved housings

-

Support body-conformal device designs

This flexibility is essential for wearable and handheld medical equipment, where industrial design directly impacts patient compliance.

Lightweight Construction

Reducing device weight improves:

-

Patient comfort

-

Long-term wearability

-

User adoption for home medical devices

LiPo batteries achieve high energy density without metal casing, resulting in lighter total system weight.

Stable Voltage and Low Self-Discharge

Medical devices often require:

-

Consistent sensor accuracy

-

Predictable discharge curves

-

Minimal power drift over time

LiPo chemistry provides stable voltage output and low self-discharge, supporting reliable readings even after long storage periods.

High Reliability for Near-Medical Applications

Although not all health devices are classified as medical devices, near-medical electronics still demand:

-

High-quality cells

-

Documented testing

-

Lot-level traceability

LiPo batteries from qualified suppliers meet these expectations when properly designed and validated.

Typical LiPo Battery Specifications for Medical Applications

Capacity Ranges by Device Type

| Device Category | Typical Capacity Range |

|---|---|

| Tiny sensors & patches | 150–800mAh |

| Portable meters | 500–1500mAh |

| Smart monitors | 800–2000mAh |

| Nebulizers & handheld devices | 1500–3000mAh |

Capacity selection should always consider actual load profile, duty cycle, and expected daily usage.

Voltage and Configuration

Most medical LiPo batteries use:

-

Nominal voltage: 3.7V

-

Fully charged: 4.2V

-

Single-cell configuration

Multi-cell designs are rare due to complexity and certification burden.

Mechanical Form Factors

Common designs include:

-

Ultra-thin pouch cells (4–6 mm for wearables)

-

Rectangular flat cells for handheld devices

-

Custom-shaped cells to match enclosure contours

Flexible leads and reinforced tabs are often specified for reliability under repeated handling.

Safety and Certifications: What Medical Devices Require

IEC 62133 – Battery Safety Standard

IEC 62133 is the core international safety standard for lithium rechargeable cells and packs used in medical and consumer electronics.

It covers:

-

Overcharge protection

-

Short-circuit safety

-

Mechanical abuse testing

Any LiPo battery used in medical equipment should comply with IEC 62133.

IEC 60601 – Medical Device System Level

IEC 60601 applies to the complete medical device, not the battery alone.

Battery considerations include:

-

Electrical isolation

-

Thermal behavior

-

Integration with protective circuits

Manufacturers must ensure battery design supports system-level compliance.

UN38.3 – Transportation Compliance

All lithium batteries shipped internationally must pass UN38.3 testing, covering:

-

Altitude simulation

-

Vibration and shock

-

Thermal cycling

Without UN38.3 documentation, logistics delays and shipment rejections are common.

Traceability and Documentation

For medical or near-medical products, best practice includes:

-

Batch-level traceability

-

Production records

-

Test reports linked to serial numbers

This supports audits, recalls, and long-term quality assurance.

Selection Tips: Choosing the Right LiPo Battery for Medical Devices

-

Define the real load profile, not just nominal current

-

Prioritize safety certifications over lowest cost

-

Match thickness to industrial design early

-

Specify cycle life based on actual usage, not marketing claims

-

Work with suppliers experienced in medical applications

From our experience, early battery selection decisions significantly reduce redesign risk during certification.

Reliability and Lifecycle Considerations

Medical devices often have longer expected service life than consumer gadgets.

Important factors:

-

≥500 stable charge cycles

-

Controlled aging behavior

-

Predictable capacity fade

Proper battery selection improves:

-

Device uptime

-

Patient trust

-

Regulatory compliance

H2

External and Internal Reference Links (Authority & EEAT)

External References

-

IEC Official Standards Overview

https://www.iec.ch -

WHO – Medical Device Technical Guidance

https://www.who.int/teams/health-product-policy-and-standards

Internal Link Suggestions

-

Lithium Polymer Battery Custom Solutions

-

3.7V Lithium Battery Design Guide

-

Battery Safety Standards for Medical Devices

(These internal links strengthen topical authority and crawl depth.)

Frequently Asked Questions (FAQ)

Are LiPo batteries safe for medical devices?

Yes. When designed correctly and certified to IEC 62133, LiPo batteries are widely used in regulated medical and health monitoring equipment.

What thickness LiPo battery is typical for wearable medical devices?

Most wearable health devices use pouch cells between 4–6 mm thick, depending on capacity and housing design.

Do medical LiPo batteries require special certification?

The battery itself requires IEC 62133 and UN38.3. The complete device must comply with IEC 60601 if classified as a medical device.

How long do LiPo batteries last in health monitoring equipment?

Typically 300–800 charge cycles, depending on depth of discharge, charging method, and operating conditions.

Conclusion: Building Safer, Smaller, More Reliable Medical Devices

As healthcare continues moving toward portable, connected, and patient-centric devices, lithium LiPo batteries will remain a core enabling technology. Their slim profile, mechanical flexibility, stable performance, and certification readiness make them particularly well suited for medical and health monitoring equipment.

By selecting the right LiPo battery early—and working with experienced suppliers—manufacturers can reduce certification risk, improve product reliability, and deliver safer devices to patients worldwide.

Related articles:

3.7V LiPo Battery Applications: an industry guide

Lithium LiPo Battery for Portable Consumer Electronic Devices

Lithium LiPo Battery for Beauty Products (K-Beauty & Beyond)

3.7V Lithium Battery Customization: A Complete OEM & Engineering Guide

Custom LiPo Battery: OEM Lithium Polymer Battery Solutions Built for Your Product

-

May.2026.01.23Lithium LiPo Battery for Internet of Things (IoT) and Smart HardwareLearn More

May.2026.01.23Lithium LiPo Battery for Internet of Things (IoT) and Smart HardwareLearn More -

May.2026.01.22Lithium LiPo Battery for Medical and Health Monitoring EquipmentLearn More

May.2026.01.22Lithium LiPo Battery for Medical and Health Monitoring EquipmentLearn More -

May.2026.01.22Lithium LiPo Battery for Beauty Products (K-Beauty & Beyond)Learn More

May.2026.01.22Lithium LiPo Battery for Beauty Products (K-Beauty & Beyond)Learn More -

May.2026.01.22Lithium LiPo Battery for Portable Consumer Electronic DevicesLearn More

May.2026.01.22Lithium LiPo Battery for Portable Consumer Electronic DevicesLearn More -

May.2026.01.2114500 Battery vs AA Battery: A Complete Technical and Application GuideLearn More

May.2026.01.2114500 Battery vs AA Battery: A Complete Technical and Application GuideLearn More