Lithium LiPo Battery for Electric Toys and Models (Drones, RC)

When I first entered the RC hobby world, I quickly realized that LiPo (Lithium Polymer) batteries are not just a component—they are the “engine” of the model. Their ability to deliver high bursts of current, while staying light and compact, is the reason they dominate drones, RC cars, boats, and small UAV systems.

In this guide, I’ll walk you through why LiPo batteries are essential, how to choose the right pack, what safety practices matter, and how to optimize performance for your electric toys and models.

1. Why LiPo Batteries Are the Standard for Drones and RC Models

1.1 High Discharge Performance (C-Rate)

The single most important advantage of LiPo batteries in the RC world is high discharge capability.

LiPo cells can deliver high peak currents, which is exactly what brushless motors need during acceleration, climbing, or high-speed bursts. The C-rate is the industry-standard measurement for this capability:

-

5C – basic performance, suitable for low-power models

-

10C – common for micro drones and basic RC cars

-

20–50C – high-performance drones and RC models

Why C-rate matters

If you choose a pack with a lower C-rate than required, the battery will overheat, voltage will sag, and your motor will not perform as expected. This is a common cause of loss of control or sudden power drops.

1.2 Power-to-Weight Advantage

Compared to legacy NiMH packs, LiPo batteries offer:

-

Higher energy density

-

Lower weight

-

Smaller size

This is why drone manufacturers choose LiPo for payload-sensitive applications such as aerial photography, FPV racing, and professional UAV systems.

1.3 Voltage Stability

LiPo cells maintain stable voltage under load better than many other chemistries. This matters because:

-

ESCs (Electronic Speed Controllers) need stable voltage to maintain throttle response

-

Camera drones require stable power to avoid image artifacts

-

GPS trackers and UAV systems require steady voltage for sensors and communication modules

2. Use Cases: Where LiPo Batteries Excel in RC and UAV Systems

2.1 Small Aerial Photography Drones

For drones, battery selection directly affects:

-

flight time

-

stability

-

thrust

-

payload capability

Typical LiPo packs used in small camera drones:

| Drone Type | Typical Capacity | Typical C-Rate | Notes |

|---|---|---|---|

| Micro drones | 300–700 mAh | 10–20C | Light weight, short flight time |

| Racing drones | 850–1500 mAh | 30–50C | High burst power, fast response |

| Camera drones | 1500–5000 mAh | 15–30C | Longer flight time, stable power |

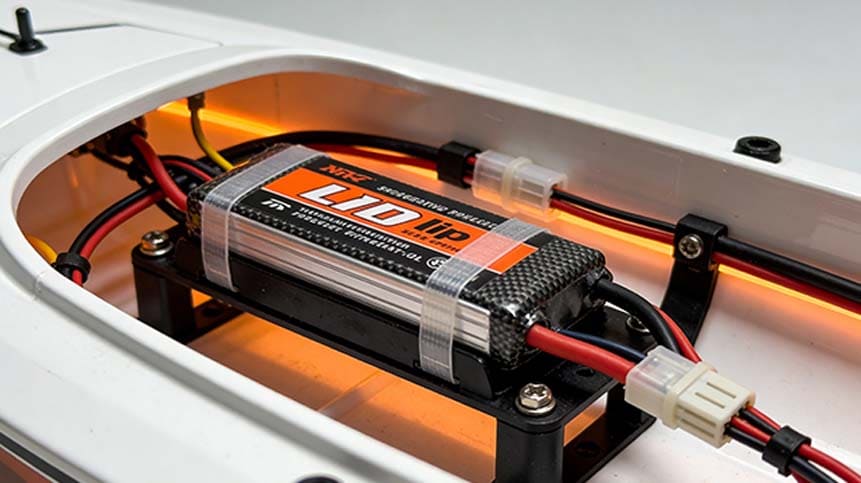

2.2 RC Cars and Boats

RC cars and boats require rapid bursts of power and high torque. LiPo batteries allow:

-

faster acceleration

-

higher top speed

-

better handling due to lower weight

Typical LiPo packs used:

| Model Type | Typical Capacity | Typical C-Rate | Notes |

|---|---|---|---|

| RC cars (1/10 scale) | 2200–5000 mAh | 20–50C | High performance |

| RC boats | 3000–6000 mAh | 20–60C | Heavy load, water resistance needed |

|

|

2.3 Backup Power for UAV Systems

Many UAV systems need backup power for:

-

GPS modules

-

communication modules

-

fail-safe systems

LiPo packs are preferred because they can:

-

deliver power instantly

-

remain lightweight

-

be sized for compact compartments

3. Typical Specs & Selection Tips (The Practical Guide)

3.1 C-Rate Selection: Match Motor Amp Draw

When I select a LiPo pack, I always start by calculating the motor’s maximum current draw.

Formula:

Required continuous discharge current (A) = motor amp draw × safety margin (20–30%)

Then choose a pack whose continuous C-rate rating exceeds this value.

Example

If your motor draws 30A at peak:

-

Required pack: 30A × 1.3 = 39A

-

If pack is 2200 mAh:

C-rate required = 39A / 2.2Ah = 17.7C

So you should choose at least a 20C pack for safety.

3.2 Capacity Selection: Weight vs Flight Time

Battery capacity determines how long your model can run, but it also adds weight.

Typical ranges:

-

Micro drones: 300–1500 mAh

-

Standard drones: 1500–5000 mAh

-

Large drones: 5000–10000 mAh or more

Practical selection

I usually choose the battery based on:

-

desired flight time

-

payload weight

-

model balance

If you need longer flight time, increase capacity—but keep in mind the tradeoff with weight and performance.

3.3 Voltage (Cell Count)

LiPo cells are rated at:

-

3.7V nominal per cell

-

4.2V fully charged per cell

Common configurations:

| Cell Count | Nominal Voltage | Common Use |

|---|---|---|

| 2S | 7.4V | Micro drones, small RC cars |

| 3S | 11.1V | Standard drones, RC models |

| 4S | 14.8V | High performance drones |

| 6S | 22.2V | Racing drones, heavy load systems |

4. Safety: Why Proper LiPo Handling is Non-Negotiable

LiPo batteries store a lot of energy in a small package, and misuse can cause fire or damage.

4.1 Mechanical Fixation and Vibration Damping

In RC models, vibration is constant. I always recommend:

-

secure mounting using straps or foam

-

vibration damping to protect solder joints

-

anti-slip pads to prevent movement

4.2 Connectors and Wiring

Connector quality affects performance and safety:

-

XT60 / XT90 are common and reliable

-

avoid cheap connectors that overheat

-

always use thick enough wiring for the current

4.3 Charging Practices

Charging is where most LiPo incidents occur. I follow these rules:

-

Use a proper LiPo balance charger

-

Always charge in a fireproof bag

-

Never leave charging unattended

-

Ensure correct cell count and charge rate (C-rate limit)

Recommended charge rate

A safe charge rate is typically 1C:

-

2200 mAh → charge at 2.2A

-

5000 mAh → charge at 5A

Higher rates are possible but increase risk and reduce battery lifespan.

5. Performance Optimization: How to Get the Best Out of LiPo Packs

5.1 Avoid Over-Discharge

LiPo cells should never be discharged below:

-

3.0V per cell (minimum safe)

-

3.2–3.4V per cell for long life

If your ESC or telemetry shows voltage sag, stop flying and land immediately.

5.2 Temperature Management

Heat reduces battery life and increases risk.

-

Keep batteries cool during flight

-

Avoid charging in hot environments

-

Use heat-resistant foam or insulation for motors and ESCs

5.3 Storage Voltage

If you won’t use a LiPo pack for more than a few days:

-

store at 3.8–3.85V per cell

-

never store fully charged or fully discharged

6. Data-Driven Selection: Real-World Performance Table

Below is a realistic, industry-standard reference table based on typical hobby LiPo performance data:

| Pack Type | Typical Capacity | Typical C-Rate | Estimated Continuous Current | Typical Use |

|---|---|---|---|---|

| 2S 500mAh | 500 mAh | 20C | 10A | micro drone, FPV |

| 3S 1000mAh | 1000 mAh | 30C | 30A | small drone, RC car |

| 3S 2200mAh | 2200 mAh | 40C | 88A | high performance RC |

| 4S 1500mAh | 1500 mAh | 50C | 75A | racing drone |

| 6S 1300mAh | 1300 mAh | 75C | 97.5A | pro racing UAV |

7. Brand & Entity Authority : Why You Should Choose a Trusted LiPo Supplier

In my experience, battery performance is not just about specs—it’s about consistency and quality control.

A reputable manufacturer provides:

-

stable cell chemistry

-

consistent internal resistance

-

reliable safety mechanisms

-

accurate capacity and discharge ratings

At A&S Power, we follow strict quality control and testing protocols to ensure each pack performs as expected under real-world conditions.

9. FAQ: Common Questions About LiPo Batteries for RC and Drones

Q1: What C-rate do I need for my drone?

A: Choose a pack whose continuous discharge rating exceeds your motor’s maximum current draw by 20–30%. For small models, 5–10C is common; high-performance drones often need 20–50C packs.

Q2: How long will a LiPo battery last?

A: Lifespan depends on charge cycles, temperature, discharge depth, and storage. Typical lifespan is 100–300 cycles, with careful handling increasing longevity.

Q3: Can I use a LiPo battery for a boat?

A: Yes, but choose a pack with higher capacity and higher C-rate due to heavy load and water resistance demands.

Q4: Is LiPo safer than NiMH?

A: LiPo offers better performance and lighter weight, but NiMH is generally more tolerant of misuse. With correct handling, LiPo is safe and more powerful for RC applications.

Q5: What is the best charger for LiPo batteries?

A: Use a dedicated LiPo balance charger with correct voltage and cell count settings. Avoid cheap chargers without balancing features.

Related articles:

3.7V LiPo Battery Applications: an industry guide

Lithium LiPo Battery for Portable Consumer Electronic Devices

Lithium LiPo Battery for Beauty Products (K-Beauty & Beyond)

Lithium LiPo Battery for Internet of Things (IoT) and Smart Hardware

3.7V Lithium Battery Customization: A Complete OEM & Engineering Guide

Custom LiPo Battery: OEM Lithium Polymer Battery Solutions Built for Your Product

-

May.2026.01.23Lithium LiPo Battery for Electric Toys and Models (Drones, RC)Learn More

May.2026.01.23Lithium LiPo Battery for Electric Toys and Models (Drones, RC)Learn More -

May.2026.01.23Lithium LiPo Battery for Internet of Things (IoT) and Smart HardwareLearn More

May.2026.01.23Lithium LiPo Battery for Internet of Things (IoT) and Smart HardwareLearn More -

May.2026.01.22Lithium LiPo Battery for Medical and Health Monitoring EquipmentLearn More

May.2026.01.22Lithium LiPo Battery for Medical and Health Monitoring EquipmentLearn More -

May.2026.01.22Lithium LiPo Battery for Beauty Products (K-Beauty & Beyond)Learn More

May.2026.01.22Lithium LiPo Battery for Beauty Products (K-Beauty & Beyond)Learn More -

May.2026.01.22Lithium LiPo Battery for Portable Consumer Electronic DevicesLearn More

May.2026.01.22Lithium LiPo Battery for Portable Consumer Electronic DevicesLearn More